Pump & Treat Systems: A Resurgence

When it comes to fashion, vintage trends always seem to come around again and again. When it comes to remediation, different technologies are popular for a time and then settle into more of a niche application, as they are supplanted by the latest and greatest technological innovations.

Over the past 40 years, the remediation industry has seen different remedial technologies rise and fall in popularity:

- 1980s – Dig & Dump, and Pump & Treat

- 1990s – Biopiles, Permeable Reactive Barriers, Risk Assessments

- 2000s – Chemical Oxidation, Chemical Reduction, More Bioremediation

- 2010s – High Resolution Site Characterization, Activated Carbon-Based Amendments

And now in the 2020s, one of the remedial technologies of the 1980s has come back around and is once again very much in fashion.

Bon Jovi, 1986, Slippery When Wet Tour

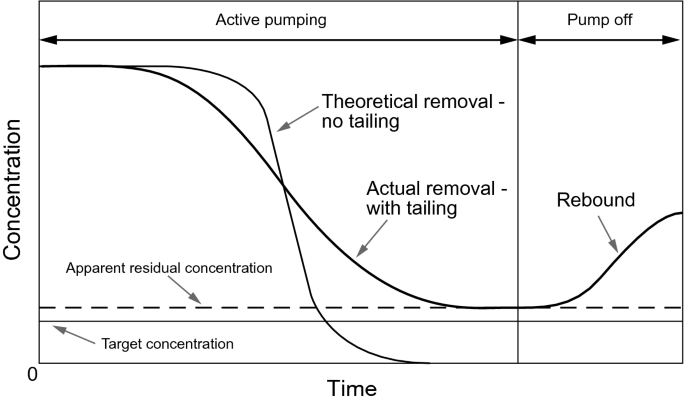

It was originally believed that Pump & Treat (P&T) systems could remediate groundwater contamination at all types of sites to low concentrations. Between 1982-1992, 73% of all Superfund sites in the US used P&T systems. However, over the years, several issues were identified with P&T including so-called “Tailing” and “Rebound”. P&T systems were being operated for many years and contaminant concentrations would reach an asymptote; then once the system was turned off rebound would occur with concentrations often rising back above the treatment objective or regulatory standard. Overall, it was very difficult to reduce dissolved-phase contaminants to below generic standards using P&T systems.

Concentration versus pumping time showing tailing and rebound effects (mod. from Keely, 1989)

So why is the demand for P&T systems on the rebound (pun intended) in the 2020s? Well, there are three main factors that are driving this resurgence.

Factor #1 – Dissolved Metals & New Construction

In major urban areas, new construction often involves the installation of underground parking levels that intersect or go below the water table; the construction of three to five levels of underground parking is not uncommon in Toronto. Groundwater management is required during construction as well as over the lifetime of the buildings.

Construction site in Toronto with four levels of underground parking

Currently, many municipalities are moving to limit the discharge of groundwater into sanitary sewers during construction and over the lifetime of these buildings. This is being done to preserve sewer capacity for conveyance of sanitary sewage and to sustain future development growth.

The result has been a shift in groundwater discharge from sanitary sewers (less stringent standards) into storm sewers (more stringent standards). In 2021, Vertex completed a study of 43 construction sites in Toronto and found that dissolved metals exceeded the sanitary sewer standards on only 3% of sites; whereas dissolved metals exceeded the storm sewer standards at a whopping 91% of sites even after correcting for elevated Total Suspended Solids.

The regulatory shift to storm sewer discharge has fueled a resurgence in Pump & Treat systems, especially to address dissolved metals. These systems are not held back by Tailing & Rebound concerns because the purpose of these systems is to polish groundwater concentrations down to applicable discharge Standards; not address the source itself, which can often be naturally occurring metals like manganese. Vertex has been involved with dozens of sites to install dewatering extraction systems during construction with pre-treatment systems that use filtration, ion-exchange media, or other additives to meet the applicable storm sewer discharge standards, as well as permanent groundwater treatment systems in building basements to address dissolved metal concentrations over the lifetime of the building.

Dissolved metals and storm sewer discharge standards is one of the most significant current factors driving the resurgence of Pump & Treat technologies.

Factor #2 – PFAS

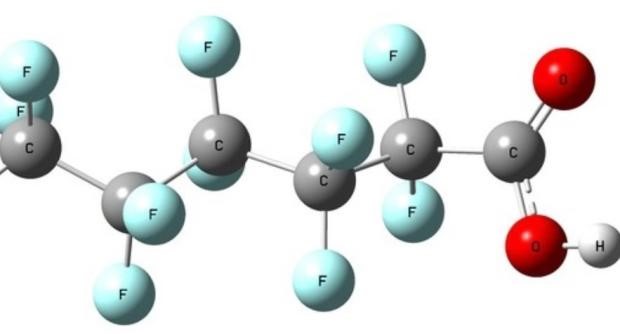

Per- and polyfluoroalkyl substances (PFAS) are a group of synthetic chemicals that have been used as ingredients in a wide variety of products since the 1940s, from non-stick cookware surfaces to firefighting foams. PFAS substances were widely used because of their strong carbon-fluorine bond which does not degrade naturally or easily. People can be exposed to PFAS-impacted food or water, and one report by the Center for Disease Control found PFAS in the blood of 97% of Americans. There is evidence that continued exposure above specific levels to certain PFAS may lead to adverse human health effects.

Conceptual PFAS molecule

PFAS is considered an emerging contaminant in Canada and does not currently have groundwater remediation standards per se, but they are no doubt coming. As of April, 2019 Health Canada has established drinking water quality guidelines for to two highest profile PFAS compounds, perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS), as well as drinking water screening standards for nine other PFAS compounds. In December, 2021, in the Minister’s annual report on drinking water, Ontario recommended that PFAS in drinking water should be addressed if the combined level of the same eleven PFAS compounds is above 70 ng/L – in effect recommending that these chemicals be treated as a class as opposed to individual compounds.

A variety of different technologies are being studied for addressing PFAS groundwater impacts in situ, including oxidation, immobilization, and thermal treatment. Over the past few years, Vertex has been involved with a number of PFAS pilot-tests in Ontario that utilized P&T and adsorption technologies, including a variation of the PRB called a PAB or Permeable Adsorptive Barrier. However, the most reliable approach for addressing PFAS is currently Pump & Treat systems that extract PFAS-impacted groundwater, and then remove the PFAS via physical adsorption methods such as granular active carbon or ion-exchange resins.

So, while the PFAS remediation market is still in its infancy in Canada, as soon as Federal and/or Provincial soil and groundwater remediation standards are released there will be a significant need to address PFAS contamination that will increase the demand for P&T systems even more.

Factor #3 – Multi-Technology Remediations

In the past, a single remedial technology was often selected for a site, and then if that didn’t achieve complete success, another technology was tried. However, a growing consensus in the remediation field is that a higher degree of success can be achieved by combining various remedial technologies into a comprehensive remedial program; one size does not fit all approach!

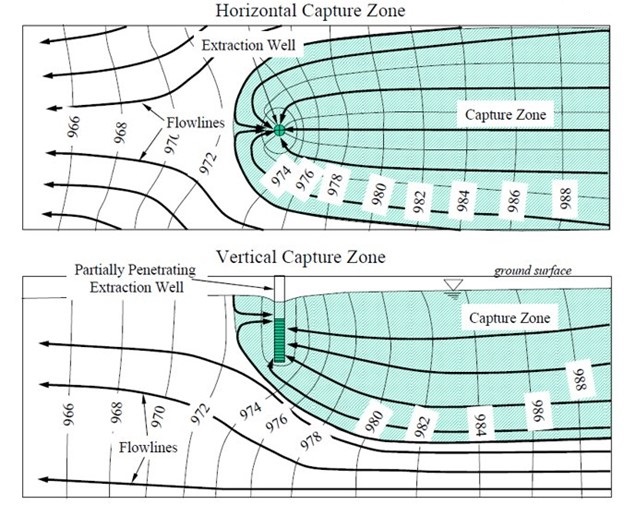

The most popular technology to combine with other remedial approaches is, you probably guessed it, Pump & Treat systems. Vertex has been involved with numerous in situ remediation projects where P&T technologies were combined with in situ chemical oxidation or in situ biological treatment programs. Back in April 2017 we presented a case study in our newsletter on combining excavation, dewatering, P&T and ISCO. P&T systems can also be used to create an enhanced gradient for improved delivery of remedial amendments underneath buildings or to inaccessible areas. P&T systems can also be used to recirculate amendments through a plume, or even protect a downgradient receptor or property boundary from unwanted influence via hydraulic control.

The use of P&T systems in multi-technology remediation programs is the third factor driving a resurgence in P&T systems.

Flow net showing the horizontal and vertical capture zones of a partially penetrating extraction well

So, just like vintage fashion trends that come around again, P&T is currently experiencing a resurgence, and the 2020s just might be remembered as a decade when Pump & Treat was popular again. And while there are inevitably still some big Bon Jovi fans out there, we would guess that the fan base of P&T systems is growing at much a faster rate!

The case study presented in the second part of this newsletter is an example where P&T technologies were leveraged to enhance the delivery of sodium persulphate under an inaccessible building, as part of a Multi-Technology Remediation.

Feel free to contact Vertex Environmental if you have any questions regarding Pump & Treat systems or for any other remediation need.