Groundwater is not conducive to civil construction projects. Successfully removing water by reducing water table levels is a critical component of infrastructure and excavation projects.

Some sites may require dewatering 24/7 when the water table is higher than the proposed excavation depth. On these sites the water level can be lowered to create a safe, dry environment for excavation using a wellpoint pumping system and piping.

The same pumping system can be used on short term projects and is often utilized in the construction of storm and sanitary pipelines.

Vertex can supply well point dewatering systems with pumping capacity up to 300 GPM and a vacuum lift up to 30 ft on our wellpoint dewatering systems.

With a combination of experience and products, Vertex Environmental can ensure the job is done correctly and safely.

Unstable slopes and retaining walls. Delayed movements of foundations.

The dewatering process ensures the soil is dry prior to excavation. Pumping removes excess water on the ground’s surface and subsurface, which will help firm up the soil. If done properly, dewatering prevents soil erosion and upheaval failure.

There are several important dewatering methods including:

- Wellpoint method of dewatering

- Open sump pumping and.

- Deep wellpoint method.

Construction Dewatering Options

A variety of techniques to install construction dewatering systems

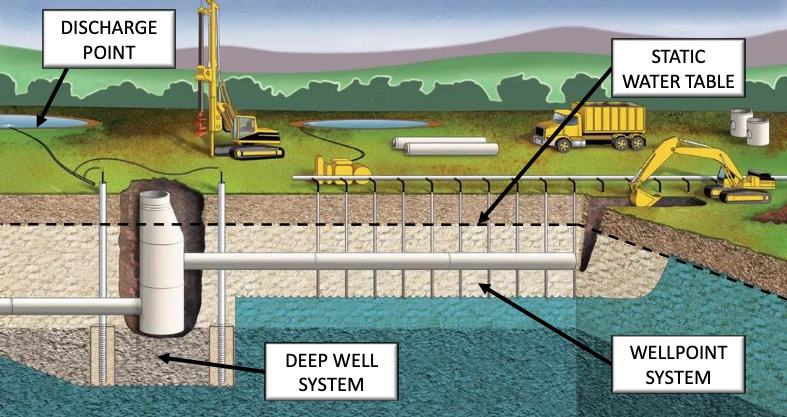

The most common dewatering system is Wellpoint dewatering. A typical wellpoint dewatering system consists of a series of extraction wellpoints located around the perimeter of the excavation, a collection header piping system, and a diesel piston pump operating at surface.

If required, a wellpoint dewatering system can be located at the bottom of an excavation or in a confined space, with a modified collection system and electric powered pump.

Wellpoint dewatering systems are fast to install and a very effective method for depths up to 20 feet.

Projects that require deeper drawdown (i.e., greater than 20 ft) would typically require an eductor or deep well system. Deep well systems take longer to install but often require fewer wells than a traditional wellpoint system.

Vertex Environmental employs a variety of techniques to install construction dewatering systems including Sonic drilling, hollow and solid stem augers, and jetting.

Benefits of Construction Dewatering

- Job Safety: As a contractor, your workers’ safety should be a priority. Constructing a structure on the muddy ground can pose significant risks to workers on site. The wet soil can lead to accidents for the workers, who might end up getting injured. It can even compromise the stability of the structures under construction and obstruct some tasks. Not to mention, too much water can also damage the equipment used on the construction site, impeding operations.

- Prepares the Soil: Laying a foundation on wet soil can weaken the structure under construction. That’s why you need dry soil before excavation. To dry damp soil, you need to drain the underground water using the right dewatering method, such as pumping. That will firm up the ground and make it ideal for construction. Pro Tip: Dry soil lowers the risk of run-offs that carry away sediments, reducing soil erosion. It also helps to stabilize the landscape for safe construction.

- Keep Projects on Schedule: If you’re constructing a building during a rainy season, the site can flood, causing delays in delivering your work. The delicate construction equipment can also get damaged by the excess groundwater, stalling onsite operations. You may even need to spend more money to repair the destroyed equipment. To keep up with your construction project’s schedule during rainy seasons, invest in effective dewatering solutions.