OVERVIEW

Site remediation work often focuses on contamination present in soil and/or overburden groundwater. In-situ remediation of these media is relatively straight-forward using a variety of technologies as detailed on our other pages. What if your site has contamination in the bedrock that can’t be remediated via traditional methods? In the past, bedrock contamination was either not looked for, was ignored, or was addressed via Risk Assessment because of the difficulties it posed to remediation. Fortunately, that no longer needs to be the case!

Figure 1: Bedrock Cores Showing Fractures and Bedding Planes

REMEDIATION TECHNIQUES

With the recent shift of regulators towards requiring complete vertical delineation and remediation, bedrock contamination is becoming more and more frequently encountered, including sites that contain LNAPL (light, non-aqueous phase liquid) in the bedrock.

Figure 2: Movement of a Fresh Contaminant Source Through a Fracture Network and Eventual Diffusion into the Bedrock Matrix (source: ITRC)

There are now several ways to effectively remediate bedrock contamination, including:

- Excavation

- Injection Wells

- Open Boreholes

Excavation

Excavation can be an effective means to remediate accessible bedrock (i.e., not too deep, not beneath a building, etc.) and Vertex has partnerships with many excavation contracting firms that we work with to complete the excavation component of site remediation activities. However, most often it is only the groundwater within the bedrock fractures that is contaminated. In that scenario excavation can be expensive and is most likely unnecessary.

Injection Wells

The most traditional bedrock remedial approach involves installing injection wells to deliver remedial amendments into the subsurface. This approach is very effective at remediating relatively “fresh” contamination that has not had time to diffuse into microfractures or the bulk matrix of the bedrock. Typically, liquid solutions of soluble remedial amendments are injected through such wells. Multi-level wells can also be used to target discrete fracture zones within the bedrock.

Open Boreholes

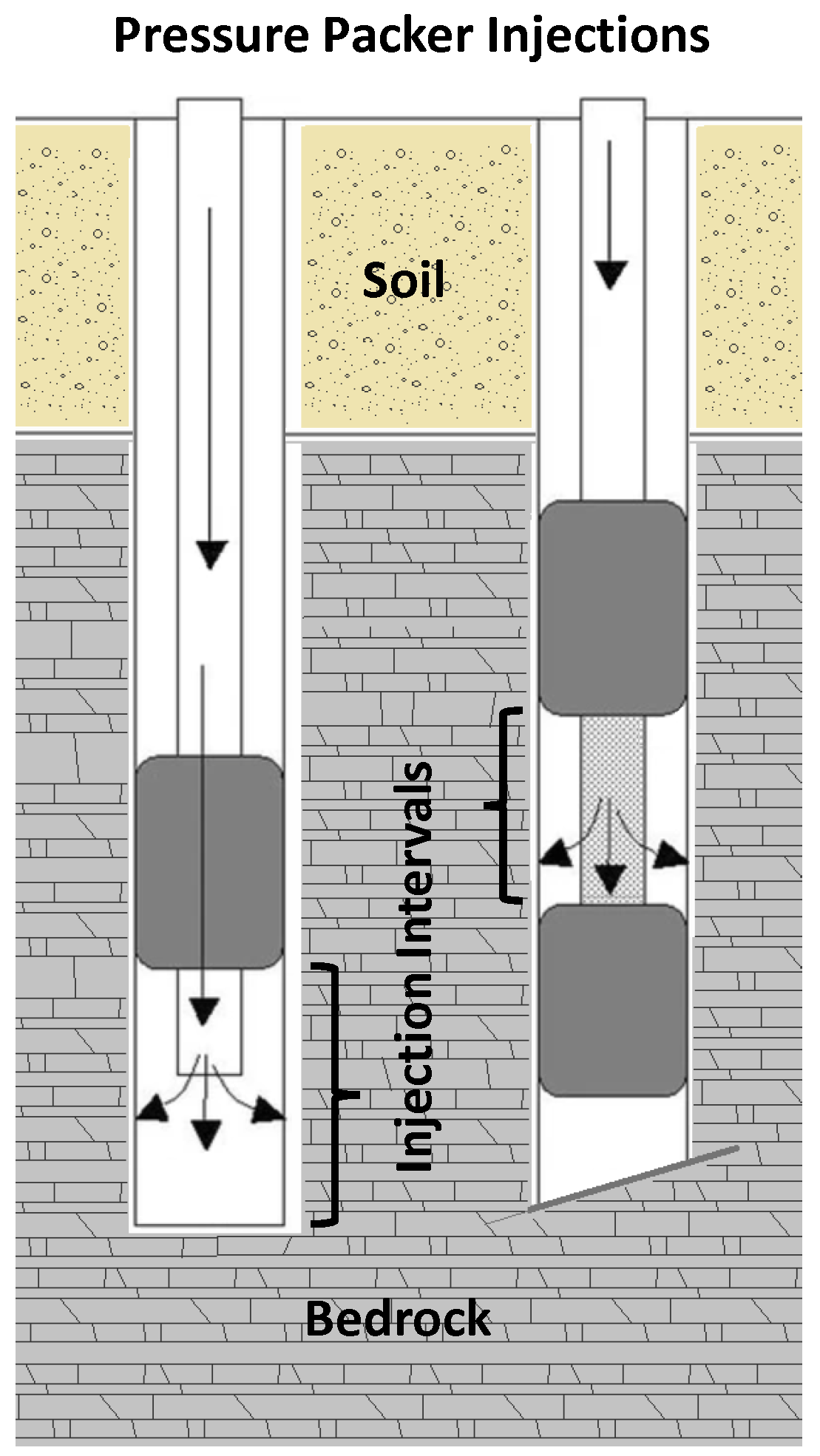

An alternate approach is to drill open boreholes in the bedrock and complete the injections using pressure-packer assemblies. Much higher pressures (compared to injection wells) can be achieved via this approach, resulting in a larger radius of influence and requiring fewer injection points. Remedial amendments in the form of particulate suspensions and slurries, as well as solutions, can be injected via this approach. Particulate remedial amendments, such as zero-valent iron (ZVI) and Trap & Treat® BOS 100® and BOS 200®, also have the advantage of offering long-lasting groundwater treatment and protection against the affects of back-diffusion of contaminants out of the bedrock matrix and back into the fracture flow pathways.

REMEDIAL APPROACHES

Contaminated bedrock can be remediated using any of the traditional in-situ technologies that can be used on soils including:

- Chemical Oxidation

- Chemical Reduction

- Trap & Treat® BOS 100® and BOS 200®

- Aerobic and Anaerobic Enhanced biodegradation

- Surfactant Flushing

- Permeable Reactive Barriers (PRBs)

- Groundwater Extraction, Containment and Treatment Systems

RECENT EXPERIENCE

The keys to the successful implementation of a bedrock remediation program is to select the most appropriate remedial amendment and apply it such that full contact with the contaminants in the subsurface is achieved. Vertex staff has experience with many bedrock remediation sites including the following selected examples:

- Excavation of petroleum hydrocarbon-impacted bedrock:

-

- Vertex partnered with a excavation contractor to excavate the source area of PHC impacts in weathered shale bedrock at a site in the Greater Toronto Hamilton Area (GTHA) and Vertex also obtained a site-specific sewer discharge agreement (SDA) to facilitate excavation dewatering and on-site groundwater treatment during the bedrock excavation program. On this site the base and sidewalls of the excavation were seeded with Trap & Treat® BOS 200® during backfilling and compaction to prevent potential recontamination.

- Injection wells for petroleum hydrocarbon-impacted bedrock:

-

- Vertex has extensive experience in remediating fuel oil / heating oil spills that have occurred into fractured bedrock, including at igneous and sedimentary bedrock sites across Ontario. Remediation of these “fresh” contaminant sources has successfully been achieved via the injection of surfactants (followed by extraction) and/or chemical oxidants, such as persulphate or percarbonate, into injection wells that intersect the impacted bedrock fractured zones and bedding planes

- Injection wells and open borehole packer injections for chlorinated solvent impacted bedrock:

-

- Vertex worked on a site in Eastern Ontario that had an extensive on-site and off-site plume of chlorinated solvent impacts in bedrock groundwater. The injection program used a combination of injection wells and open boreholes with pressure packer assemblies to introduce remedial amendments into the bedrock to facilitate combined chemical reduction (using an emulsified ZVI) and enhanced anaerobic biodegradation, including introducing a microbial inoculant (KB-1®) to facilitate complete dehalogenation of the contaminants.

- Open borehole packer injections for heavy metal-impacted bedrock:

-

- Vertex recently completed pilot-scale remedial injections at a long-term metal plating facility in Southern Ontario using open boreholes with pressure packer assemblies to introduce a slurry of zero-valent iron (ZVI) into the fractured shale bedrock to assess the feasibility of achieving source area plume remediation and protection over off-site migration of hexavalent chromium impacts in the groundwater via an injected PRB along the downgradient property line.

- Open borehole packer injections for petroleum hydrocarbon-impacted bedrock:

-

- Vertex recently completed pilot-scale and full-scale remedial injections of Trap & Treat® BOS 200® at a site in Southern Ontario that had an extensive plume of PHC impacts in shale bedrock, including several areas containing LNAPL and/or sheens. Open boreholes and pressure packers were used to inject the activated carbon-based remedial amendment into the weathered and fractured shale to achieve long-lasting adsorption of the LNAPL and long-term anaerobic biodegradation of the dissolved phase plume.

Vertex combines strong theoretical understanding with practical experience to properly plan and implement the right remedial program for your site, whether it has issues in the overburden, bedrock or both. Selecting Vertex to undertake your bedrock remediation project allows you to access a wealth of in‑situ remediation knowledge and experience.