When Remediation is a Financial Treat

Do you have an irrational fear of remediation? Does it wake you up at night sweating and trembling? You’re probably not alone. Coming face to face with prospects of site disruption, high cost and uncertain outcomes can be frightening. But it doesn’t have to be. When done properly, remediation can be a treat – and you might even end up with a nice loot bag by the time the night is over!

Case in point: the in-situ remediation of a horrendously impacted former dry cleaner site in the lower mainland area of BC.

Storm Clouds Portending the Coming Battle of Good vs Evil

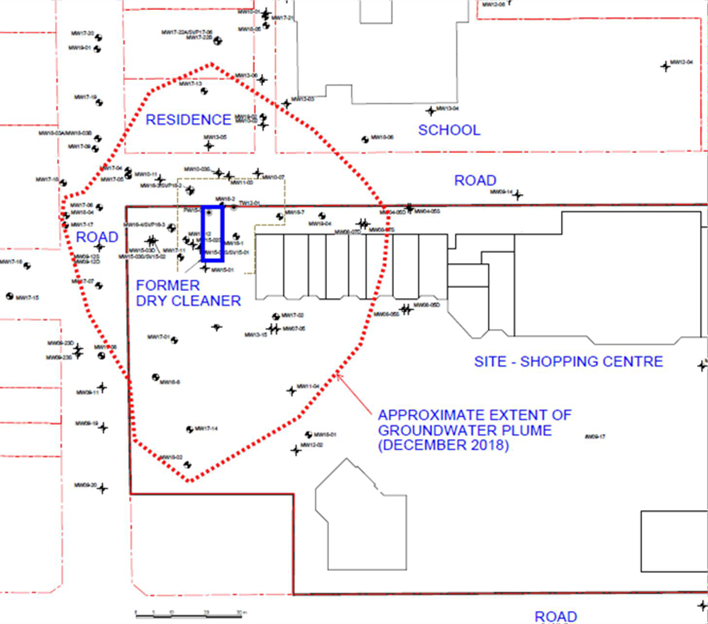

The battleground, an active shopping center, had a dark past – a dry cleaner operating in the northwest corner from the early 1960s to the late 1980s. Various environmental investigations and remediation activities had been completed since 1988 by various consultants, including excavation of 6,000 m3 of tetrachloroethylene (PCE) impacted soil in source area and in the roadway to the north, as well as installation of a perimeter groundwater extraction and treatment system to prevent further off-site migration of the groundwater plume. PCE and degradation products were present in soil, groundwater, and soil vapour at concentrations above the applicable BC CSR standards, both on-site and off-site to north and west beneath roads, a residence, and a school. Yikes!

Demon’s Lair (Former Dry Cleaner) and Groundwater Plume

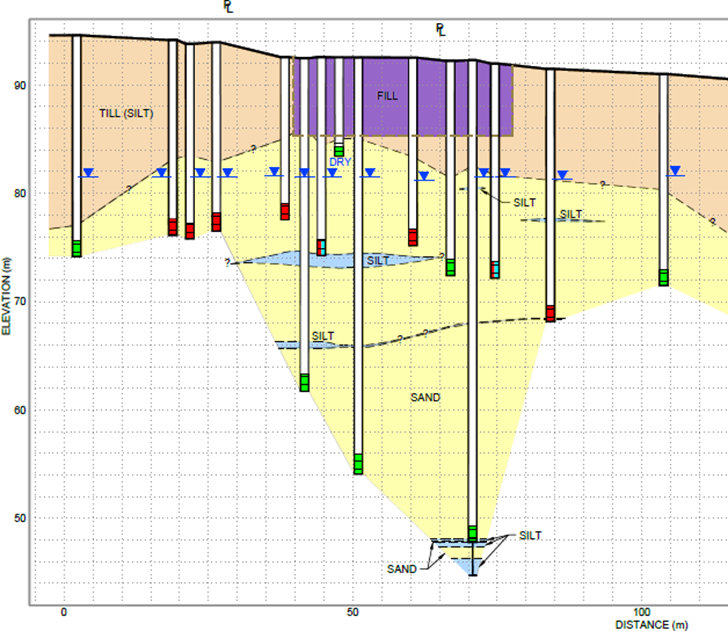

The hidden depths of the site comprised dense silt till with cobbles to 8 meters below ground surface (mbgs) followed by flowing sands to 45 mbgs and finally a lower silt confining layer. The main groundwater plume was present in the sand at depths between approximately 11 and 21 mbgs – scary deep!

Subterranean Hiding Place of the Forces of Evil

The client’s overall objective (dream?) was to reduce PCE concentrations in the subsurface to:

- Remove the site’s “High Risk” designation (top priority),

- Eliminate the need for the perimeter groundwater pump and treat system,

- Facilitate a human health and ecological Risk Assessment for the site and,

- Obtain a risk-based Certificates of Compliance from the regulator for the site and off-site affected areas.

There was no exit plan in sight: the owner could not sell, finance, redevelop or densify the site. Even if the site could be sold (at a loss) there would likely be trailing liability. Truly a terrifying situation! Or was it?

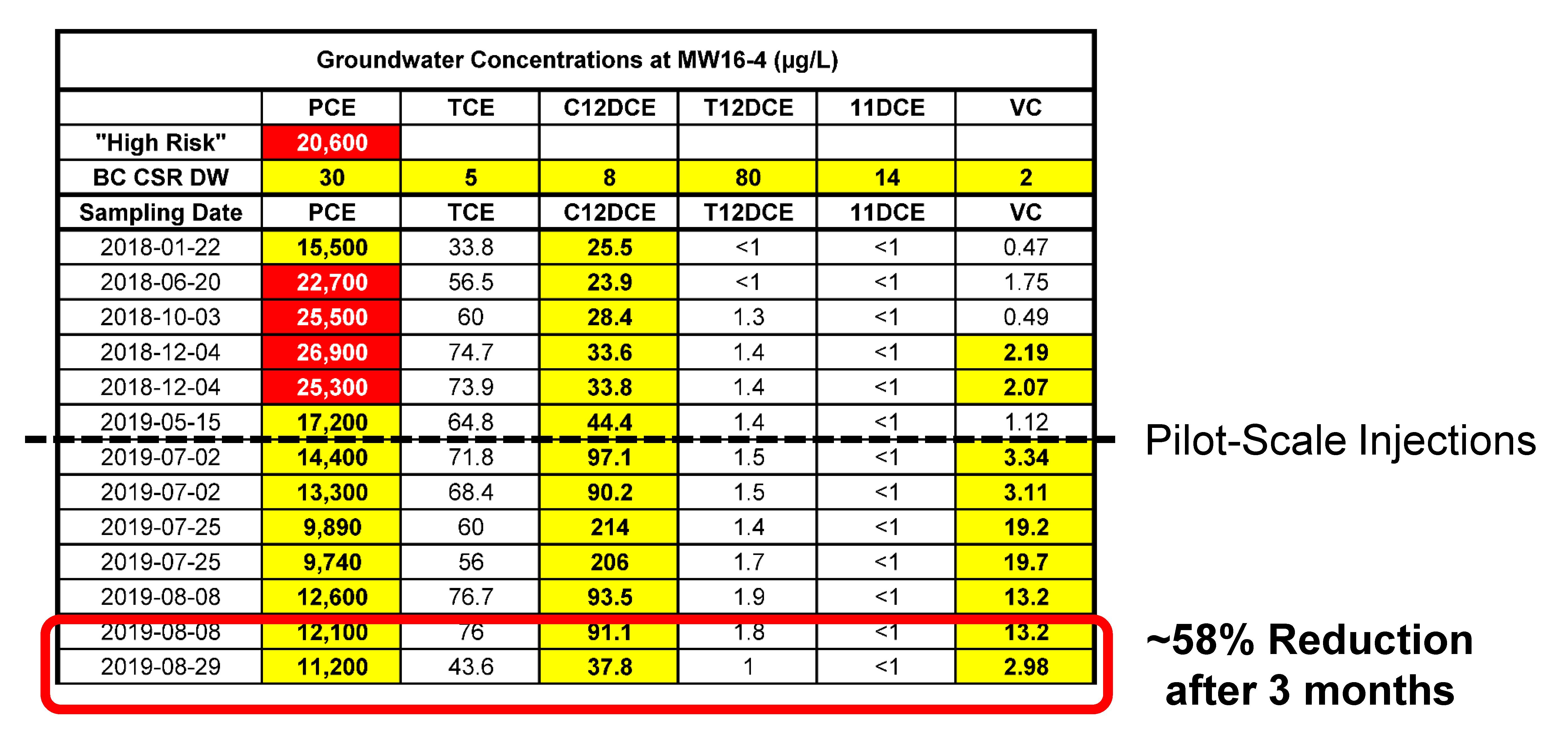

The consultant knew there had to be a better way and brought in Vertex Environmental to banish the PCE demons lurking in the hidden depths of the site. But there was a massive hoard of PCE present – concentrations up to 20,600 µg/L, potentially indicative of mobile dense, non-aqueous phase liquid (DNAPL) and, thus, triggering the “High Risk” designation. Was there a remedial technology powerful enough to overcome this evil? There just might be…

When batting demons like PCE it’s best to tackle them head-on and attack their source of power first and then go back and mop up the stragglers. A pilot-scale injection was completed in the worst-case area of the site (MW16-4). A mere 650 kg of Trap & Treat® BOS 100® in 5,500 L suspension was injected into six temporary injection points (IPs) after which two confirmatory boreholes were sampled to reveal that the remedial amendment was well distributed within targeted injection depth range. Post-injection groundwater monitoring by the consultant showed that the stronghold of the PCE had been shattered and was rapidly weakening!

Three Months Post-Injection the PCE Demons had been Routed

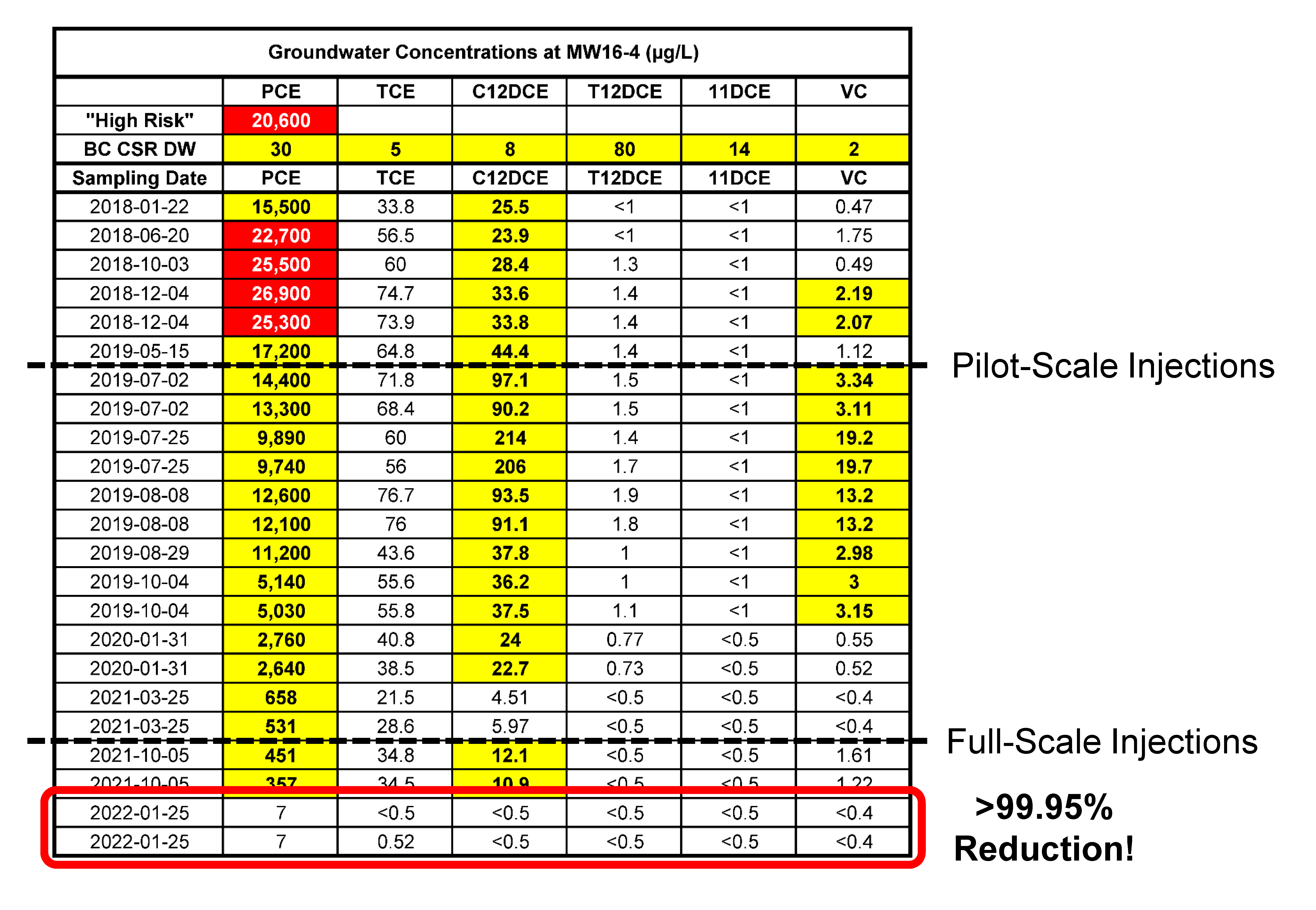

Having proven itself as a worthy adversary to the PCE, the full forces of in-situ remediation entered the battle. Over the following months a total of 23,500 kg of Trap & Treat® BOS 100® in 390,000 L of suspension was injected into 121 IPs, both on-site and off-site, over depths ranging from 8.8 to 21.3 mbgs.

Attack Plan for the Remaining PCE Infecting the Site

All the while the subterranean battle was waging conditions on the surface were relatively calm. There was barely any disruption to site operations. The in-situ remediation approach allowed continued access to, and operation of, the shopping center. No tenants were displaced. There was no loss of income during remediation and no requests for rent relief!

The Battleground: Calm on the Surface; Fierce Battle Being Waged Beneath

All that was left to do was the demon body count. How much of the PCE had been destroyed and was the victory conclusive? Groundwater monitoring over the subsequent months (five quarters in total) showed that the battle had been massively one-sided in the favour of the remediation! Upon completion of monitoring activities, the worst-case groundwater monitoring well in the center of the PCE source area had seen an incredible >99.95% reduction in concentrations!

Almost Complete Annihilation of the PCE: Victory!

Once the dust had settled (figuratively speaking) the prospects of the site were rosy:

- The perimeter groundwater treatment system was no longer required and was shut down,

- The remedial injections were proven protective of off-site sensitive receptors,

- There no longer was a requirement for long-term operation, maintenance, and monitoring costs and,

- Some zoning changes were possible now that the site was no longer considered “High Risk” and could be redeveloped.

A Brighter Future for the Site Now that the Evil has been Banished

So, what now? The site is saleable and worth full market value! Upzoning will allow densification to mixed use (commercial at grade with multi-family residential above) – the “highest and best use”. The formal property valuation has not been completed, but the owner of the site now estimates it to be worth at least two to three times the cost of the entire remediation, monitoring and risk assessment program in increased property value! That’s a nice loot bag to bring home!

In-situ remediation doesn’t have to be scary. Armed with the right technology, knowledge and experience, even the most daunting forces of contaminant evil can be vanquished. Happy Hallowe’en from Vertex Environmental!

Thank you to our partner on this project: SLR Consulting (Canada) Ltd.