Practical Risk Management Measures

Risk assessments (RAs) are an increasingly common approach towards assessing brownfields and other contaminated sites. However, in some cases RAs can identify that risk management measures (RMMs) are required to protect human health and the environment. This can comprise something as simple as a protective hard or soft cover over impacted soils, but in other cases restrictions on land use may be warranted or even regulated unless more sophisticated RMMs are implemented. RMMs may also be required from a legal liability perspective. Fortunately, today there are a variety of RMMs that can be implemented at impacted sites to facilitate their closure and/or redevelopment. This newsletter will discuss some of the more common and unusual RMMs that can be implemented including:

- Monitored Natural Attenuation (MNA)

- “Hot Spot” Remediation

- Hard or Soft Capping

- Soil Vapour Intrusion Mitigation

- Permeable Reactive Barriers (PRBs)

- LNAPL Removal / Destruction / Immobilization

Brief examples of each of these common RMMs are presented and discussed below to illustrate their effectiveness in satisfying the requirements of RAs and allowing site closure and/or redevelopment to proceed.

If you’re interested in RMMs, you may also be interested in hearing some of the experts from Vertex speak about it live. On October 4, 2023, Nathan Lichti and Farouk Abu-Hijleh will be presenting a webinar entitled “Practical Considerations for Risk Assessment and Management: A Contractor’s Perspective”. You can sign up for that webinar here: Webinar Registration – Zoom

Monitored Natural Attenuation (MNA)

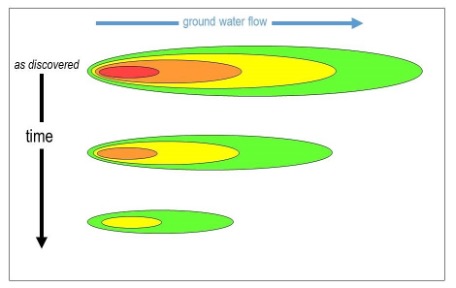

MNA relies on natural processes to decrease or “attenuate” concentrations of contaminants in soil and groundwater via various combinations of biodegradation, sorption, dilution, evaporation, and chemical reactions. MNA works best at sites where the source of contamination has been removed and these natural processes may be able to reduce the residual, lower levels of contaminants in the soil and/or groundwater to acceptable levels over time. However, this approach may take years or even decades to complete and regular monitoring is required throughout that period.

Environment and Climate Change (ECC) Canada has developed a guidance document on MNA that explains the process in a systematic and structured way. Typically, contaminants that have a high vapour pressure and low molecular weight have the highest chances of success when MNA is applied, but MNA has also been applied for some heavy metals, chlorinated solvents and even LNAPL (i.e., referred to as Natural Source Zone Depletion or NSZD).

Evolution of a plume when the source and concentrations in groundwater both attenuate

“Hot Spot” Remediation

High concentrations of contaminant mass that do not pass an RA can be addressed using several common approaches including:

- Physical removal and off-site disposal of accessible, highly impacted soil or non-aqueous phase liquid (NAPL), or

- In-situ treatment of inaccessible highly impacted soil / NAPL using injection technologies such as in-situ chemical oxidation, chemical reduction, biological means, or combinations of these.

Impacted Soil “hot spots” can be treated via removal or a variety of in-situ treatment technologies

“Hot spot” remediation might be all that is needed to lower on-site concentrations to the point where the RA will pass. These measures can be implemented “surgically” to only target the specific area(s) of the site that need remediation, reducing disruption and minimizing remedial costs.

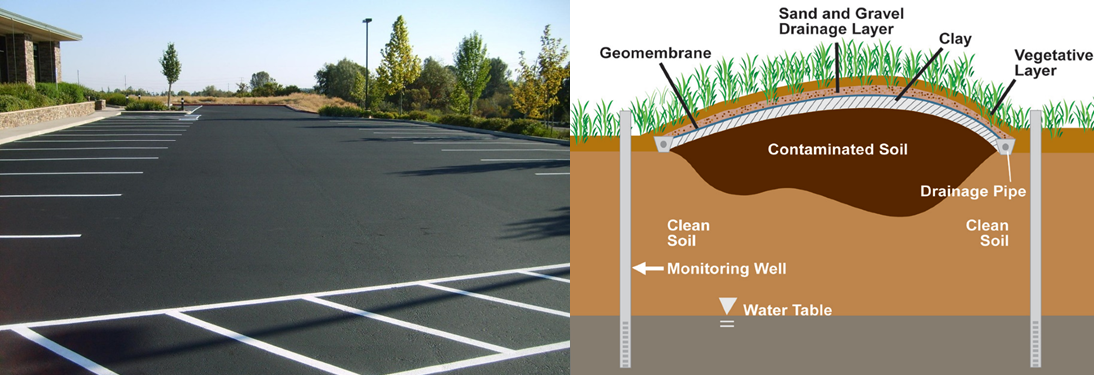

Hard or Soft Capping

Capping impacted soils can provide protection against risks associated with direct contact of impacted soils, windborne dust, surface water runoff, or even uptake by plants.

“Hard” caps can involve such basic features as:

- The building footprint, or

- Concrete or asphalt paving.

“Soft” caps typically involve:

- A clean soil cover buffer, or

- A low permeable clay cap.

Examples of “hard” (i.e., asphalt paving) and “soft” (i.e., engineered layers) soil capping measures

Capping RMMs usually require on-going inspection and maintenance requirements to ensure that the caps remain in place and are adequate to protect exposure to the underlying impacted soils. They can also restrict land use, so should ideally be incorporated into the overall design and long-term plans for the site.

Soil Vapour Intrusion Mitigation

Soil vapour intrusion mitigation RMMs come in a variety of forms and can be installed at new construction sites or retrofitted into existing, developed sites. They commonly take the form of physical barriers to intercept soil vapours and/or systems to collect and ventilate the soil vapours before they enter buildings and become a concern for indoor air quality (IAQ).

Soil vapour barriers can take the form of:

- Sheet membranes, such as Ethylene Vinyl Alcohol (EVOH), that are typically used in new construction and low-risk sites, or

A sheet membrane installed at a new construction site with sealed penetrations

- Spray-applied membranes, such as Polymer Modified Asphalt-based, that are sprayed on building foundation or sub-slab and typically used in higher-risk sites.

A spray-applied membrane being smoke tested to identify leaks requiring repair before completion

Soil vapour collection systems typically include the installation of low-profile vent piping prior to pouring floor slabs at new construction sites or cutting trenches or suction pits in existing floor slabs and installing perforated piping and clear stone before refinishing the floor slabs in existing buildings. These systems can either be passive or active, depending on the objectives and requirements for the site:

- Passive venting systems are non-energized, have low operation and maintenance (O&M) requirements and are used on lower-risk sites, whereas

- Active extraction systems are energized, have higher O&M requirements, are typically used at sites with tighter soils or higher contaminant concentrations, and provide higher vacuums and flowrates.

Perforated piping for a capture system being installed under an existing floor slab; the rooftop “whirlybird” vent for a passive soil vapour capture system

Soil vapour intrusion mitigation was the focus of one of Vertex’s newsletters a couple of years ago and contains much more information on this topic.

Permeable Reactive Barriers (PRBs)

Vertex has written and presented extensively on the benefits of PRBs over the past several years, so readers of our newsletters and conference attendees should be familiar with this technology. But just to briefly recap: PRB technology has now advanced to the point where pretty much any contaminant of concern can be treated effectively, passively and sustainably including, chlorinated solvents (CVOCs), petroleum hydrocarbons (PHCs), heavy metals, nutrients, and now even per- and polyfluoroalkyl substances (PFAS).

PRBs are perfect for intercepting and passively treating contaminated groundwater plumes. They can be used to contain plumes and prevent on- or off-site migration, protect sensitive receptors and mitigate regulatory and/or third-party liability.

PRBs can also be installed in overburden or bedrock stratigraphies using excavation, injection or GeoTAPTMapproaches.

PRBs can be installed in overburden or bedrock stratigraphies using excavation, injection or GeoTAPTMapproaches

Whatever the application, there is almost certainly a PRB that can be designed and installed at your site to serve as an effective RMM to prevent contaminated groundwater migration.

LNAPL Removal / Destruction / Immobilization

The last RMM that we will discuss in this newsletter is a bit more esoteric. In many jurisdictions across Canada, RAs can be stymied if there is mobile NAPL present. For a site with NAPL to pass an RA, mobile NAPL, and in particular LNAPL, has to either be remediated to the “extent technologically practicable” (i.e., cost is not considered a factor by regulators) or demonstrated to be “stable” and “decreasing” with the source under control. In many cases this requires long-term monitoring (i.e., in excess of a year). Even then, exposure controls and other RMMs may be needed, such as soil vapour intrusion mitigation (see above). Fortunately, there are now many ways to address LNAPL including the following.

LNAPL Removal:

Systems such as skimmers, dual-phase extraction or DPE (LNAPL and water) or multi-phase extraction or MPE (LNAPL, water and vapours) can remove mobile LNAPL mass from the subsurface. Once above surface, the extracted liquids and vapours are separated and treated. The treated vapours are discharged to the environment and the treated liquids are discharged to either the ground surface, a sewer, or re‑infiltrated back into the subsurface. The selection of which of these technologies to use (i.e., skimmers, DPE or MPE) depends on the type and amount of LNAPL present, geological and hydrological conditions, and, of course, timeframe and budget for remediation.

MPE (multi-phase extraction) systems can be highly effective at removing large amounts of LNAPL from amenable subsurface formations

LNAPL Destruction:

If only more limited amounts of LNAPL is present at a site, or the type of product or formation is not amenable to extraction, it is sometimes possible to permanently destroy the LNAPL using various chemical, adsorptive and/or biological means. Small amounts of LNAPL can be treated using in-situ chemical oxidation, but care needs to be taken to ensure that dangerous conditions are not created by the exothermic nature of the reaction. Or the LNAPL can be sorbed and degraded biologically using something like Trap & Treat® BOS 200+®.

BOS 200+® consists of activated carbon, terminal electron acceptors (TEA), additional complex carbohydrates, nutrients and a facultative blend of aerobic and anaerobic microbes. First, contaminants are adsorbed or “trapped” by the carbon, and then degraded or “treated” by biological pathways. BOS 200+® supports vigorous and persistent decomposition of LNAPL, lube oils, crude oil, etc., since it was specifically developed for significantly impacted sites and heavy PHCs. BOS 200+® is able to treat PHC LNAPL in various geologic settings including overburden materials as well as fractured bedrock environments.

Injection of Trap & Treat® BOS 200+® to destroy PHC LNAPL at a former retail fuel outlet site

LNAPL Immobilization:

What can be done though if the LNAPL at your site is so old and degraded that it poses no vapour or other risk, but is still present and mobile? In this case, removal or destruction is not needed, but immobilization can be used to facilitate the approval of the RA. Several years ago, Vertex developed a technology called “Block & Adsorb”. Essentially, Block = Portland Cement (PC) & Adsorb = Activated Carbon (GAC and/or PAC). When combined in the proper order and concentrations, they can be effective in binding mobile LNAPL and sheens of PHCs in soil and groundwater, lowering formation permeability, and reducing levels of dissolved-phase PHCs. These amendments can be emplaced using soil mixing or injection approaches. Lastly, Block & Adsorb is relatively low cost and sustainable since no wastes or excess soils are generated (a not insignificant added benefit!).

Bailer samples of water containing LNAPL (left) from a control plot and clear water (right) collected from a plot treated using Block & Adsorb

Even though sites containing LNAPL are some of the most impacted sites we encounter, there are a variety of techniques available today to remove that LNAPL to the “extent technologically practicable” and the destroy or immobilize any remaining LNAPL as an RMM to facilitate closure and RA approval.

Take Aways

There is now a large toolbox containing a wide array of RMMs that can be employed at a site to facilitate RAs including:

- Monitored Natural Attenuation (MNA)

- Allow residual contaminants to naturally decrease in concentration over time

- “Hot Spot” Remediation

- Excavate or treat to address “outliers” or sources of excessive/mobile contaminant mass

- Hard or Soft Capping

- Prevents direct exposure and plant uptake

- Soil Vapour Intrusion Mitigation

- Passive and active barriers to address indoor inhalation risks

- Permeable Reactive Barriers

- Passive control of on- or off-site migration of plumes

- LNAPL Removal / Destruction / Immobilization

- Facilitates RA acceptance and reduces risks

Each of these RMMs has its place and some sites will require more than one. But whatever the unacceptable risk at your site, there is an RMM that can be designed and implemented to allow the successful completion and acceptance of an RA-based solution. Vertex Environmental is here to assist with your RMM needs. Reach out to us at info@vertexenvironmetal.ca for more information.