Remediation at Difficult-to-Access Sites

Last February, with average temperatures ranging from -20ºC to -30ºC, we injected over 120,000 L of water-based oxidant solution at a remote site in Northern Saskatchewan. Here we share two recent case studies that further demonstrate the challenges with remote sites and difficult-to-access contamination.

Case Study #1: Formaldehyde in Northern Ontario

In May 2012 a truck carrying 35,000 L of heated waste formaldehyde crashed off highway 63. Formaldehyde and diesel were released, cascading down an embankment, along a secondary road, and down into Trout Lake – the only drinking water source for North Bay. This accident hit the front page news.

Emergency spill response actions and excavation with off-site disposal handled the gross soil impacts near the roadside. In the meantime, Vertex conducted bench scale and pilot scale testing to validate known & assumed conditions.

Formaldehyde was a novel contamination for Vertex. We started in the lab with proof of concept testing to ensure we could treat formaldehyde via chemical oxidation. With a starting concentration of just over 2,000,000 ug/L formaldehyde, a series of oxidant experiments were run to treat vials of groundwater to 20 ug/L formaldehyde in 5 days. This >99.9% concentration reduction was considered a successful proof of concept.

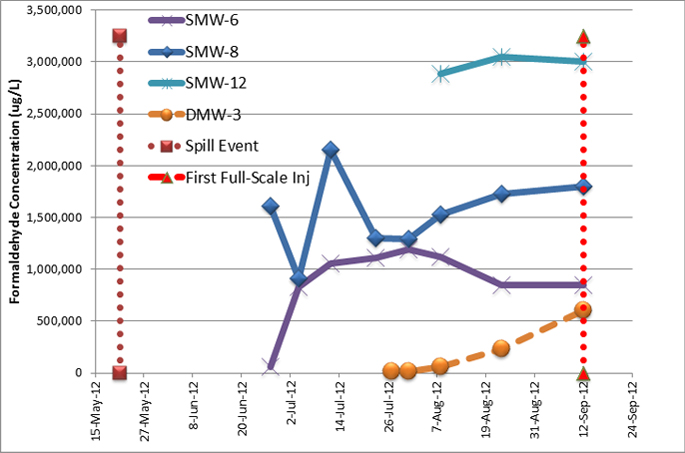

After excavation, but prior to commencement of full-scale in-situ chemical oxidation (ISCO), the groundwater data was stagnant.

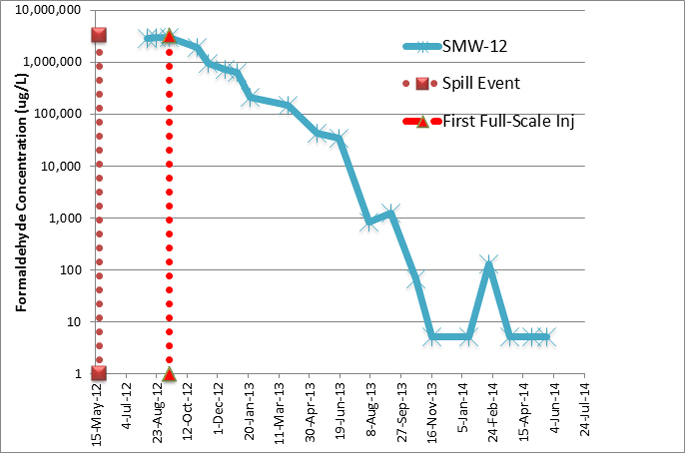

Pilot scale testing was then completed to validate the injection well design, appropriate access for our equipment, and field scale parameters critical for effective delivery of oxidants (pressure, flow, radius of influence). Moving into full scale, a series of vertical and horizontal wells were installed within Reactive Zones to provide adequate oxidant delivery. Full-scale injections started in Sept 2012, and continued periodically for months.

Below is a typical monitoring well result (shown on a logarithmic scale).

Excavation would have been very expensive & cost ineffective for the whole plume. After the limited dig to contain the gross impacts, remediation was completed using a scientific and logical approach, with excellent results. Injections were completed along a steep embankment, and during cold winter months.

Case Study #2: Heating Oil Spill in Hastings, Ontario

Heating oil leaked from an above ground storage tank (AST) in the basement of a 150 year old stone farm house. Oil entered a floor drain and migrated through cracked weeping tiles into the subsurface. Soils beneath the basement contained boulders, cobbles, and sand till over sandy silt till and were underlain by fractured limestone bedrock.

The remediation goal was for soil and groundwater quality to meet the MOE Table 2 standards for residential sites with coarse-textured soils in a potable groundwater scenario.

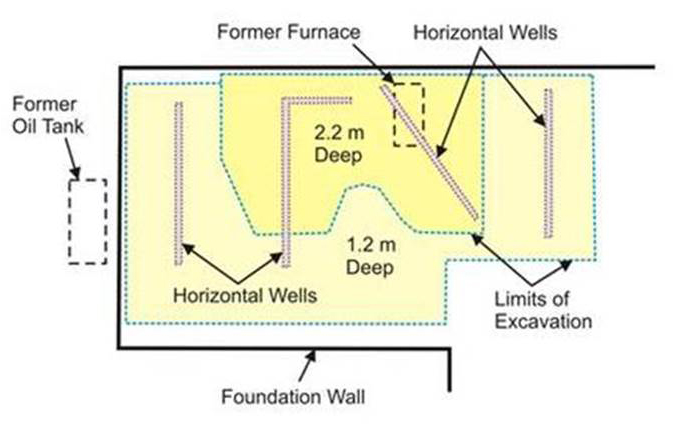

Initial remediation activities involved free product recovery, removal of the concrete floor slab and partial excavation of impacted soils, including underpinning walls and hand digging around footings. However, due to the age and construction of the home (stone foundation), the presence of undulating bedrock outcrops and the dense nature of the glacial till soils, complete excavation of the impacted soils was not practical.

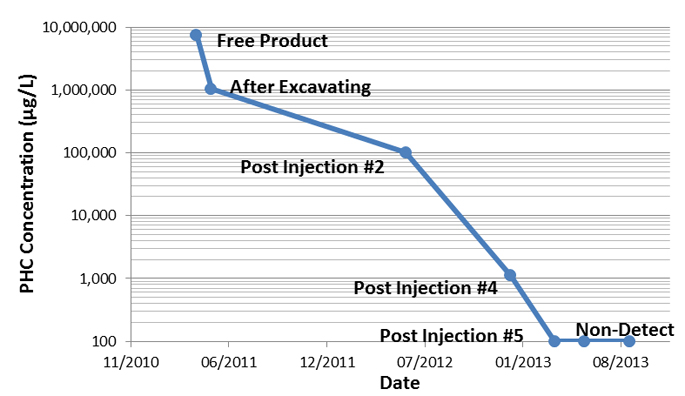

After excavation, significant PHC impacts remained, including free-phase oil in a recovery sump installed at the base of the excavation.

Managing contaminated groundwater plumes within porous media is often challenging enough. As it moves into fractured formations, the difficulties escalate. Breaking up the bedrock would be highly disruptive, very labour intensive, and an uneconomical approach.

Upon reviewing the site conditions and remedial options, Vertex developed an in-situ chemical oxidation (ISCO) remediation plan applying alkaline activated sodium persulphate. Sodium persulphate is a broad acting oxidant, able to persist in the subsurface for several weeks (important for ensuring adequate distribution and contact with contaminants). Under alkaline conditions, the persulphate is ‘activated’ and results in the generation of sulphate free radicals. These free radicals are even stronger oxidizers, highly effective at degrading longer chain hydrocarbons found in fuel oils (F2 and F3 fractions).

A series of four (4) horizontal injection wells were installed within the exposed excavation to enable injections of the oxidant solutions after backfilling. Prior to backfilling the base of the excavation was “seeded” with pure sodium persulphate and sodium hydroxide activator.

Following backfilling, Vertex completed five (5) oxidant injection events over the following year totalling 14,000 L of alkaline-activated persulphate. Two (2) interim groundwater sampling and analysis events indicated that the ISCO remediation activities were working. After the five (5) injection events were completed the analytical results for F1, F2 and F3 PHCs were all non-detect in the groundwater collected from the sump. Subsequent groundwater testing showed the results stayed “ND”.

At the end of the combined excavation and ISCO remediation activities the remedial targets (MOE Table 2) had been met and groundwater reductions were in excess of 99.9% were achieved!

These two case studies, illustrate in different ways, strategies for in situ remediation of difficult-to-access contamination. When contamination cannot be simply excavated or handled using ‘traditional’ means, sometimes we are required to get creative and like true Canadians, adapt to our challenging environment.