Collaborative Remedial Design Services

So, you’ve identified contamination at your site and are considering remediation and/or risk management. Chances are this is not your area of expertise. Perhaps you’ve had some experience with remediation in the past; perhaps not at all. Consider as well that every site is different in terms of the type(s) of contaminant(s) present, affected media, subsurface characteristics, constraints, risks, sensitivities, stakeholders, objectives, etc. With so many project / site variables and remedial options available where do you even begin? Vertex deals with these situations every day and can provide much-needed clarity and sound advice in this regard by offering collaborative remedial design services.

Remedial design is a highly technical and specialized service. It requires broad and up-to-date knowledge of available remedial amendments and technologies as well as comprehensive understanding of a wide range of science and engineering disciplines including contaminant fate and transport, geology, hydrogeology, geochemistry, reaction chemistry, delivery methods, etc. Knowledge and experience into how all of these factors interact in the real world is also necessary to be able to develop a remedial design that can be implemented at the site and have the best chance of success.

How are Remedial Designs Developed?

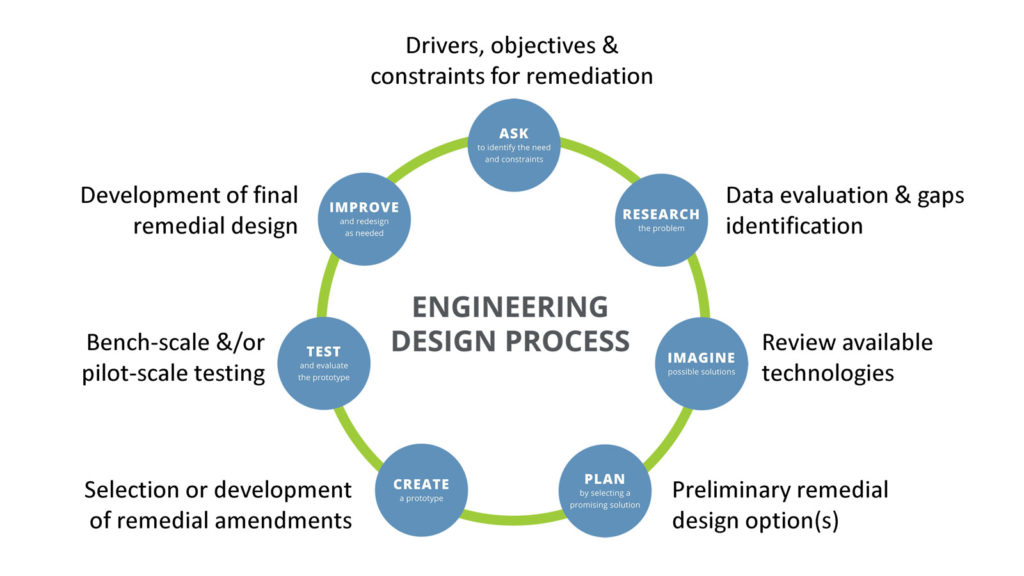

The philosophy behind our approach is simple. Vertex partners with environmental consultants and other stakeholders to collaboratively develop a thorough understanding of the conditions, challenges and objectives for each site. We then follow a standard engineering design process, specifically adapted to environmental remediation and risk management. This is summarized in the graphic below, and essentially follows a series of logical steps:

- Identify the need and constraints:

- What are the drivers and objectives for the project?

- What are the site and/or project constraints (physical, temporal, budgetary, etc.)?

- Research the problem:

- Complete an evaluation of the available data

- Identify any significant data gaps and collect additional data, as needed

- Imagine possible solutions:

- Review available remedial technologies

- Identify a short list of possible options

- Select a promising solution:

- Development of preliminary remedial design(s)

- Create a prototype:

- In this case the appropriate remedial amendments

- Are off-the-shelf products suitable?

- Are custom-made blends or entirely new amendments required?

- Test and evaluate the approach:

- Complete bench-scale feasibility (proof-of-concept) testing, as needed

- Complete pilot-scale application / implementation testing at the site, as needed

- Improve and redesign as needed:

- Incorporate all of the above into a final, preferred remedial design for the site

By following this process, you can rest assured that the final remedial design has been developed based on a thorough understanding of site conditions and project drivers, it has identified the most appropriate remedial technology to apply as well as where and how to apply it, and it includes a detailed scope, budget and schedule to implement it at the site.

For clients interested in minimizing uncertainty and maximizing the likelihood of remedial success there is no better way to go!

How Much Information is Needed to Develop a Remedial Design?

This is a frequently asked question.

There is a bare minimum amount of information and data that is required to develop a remedial design. This usually constitutes a “data package”, most of which information can be found in a standard Phase II Environmental Site Assessment report or Conceptual Site Model (CSM):

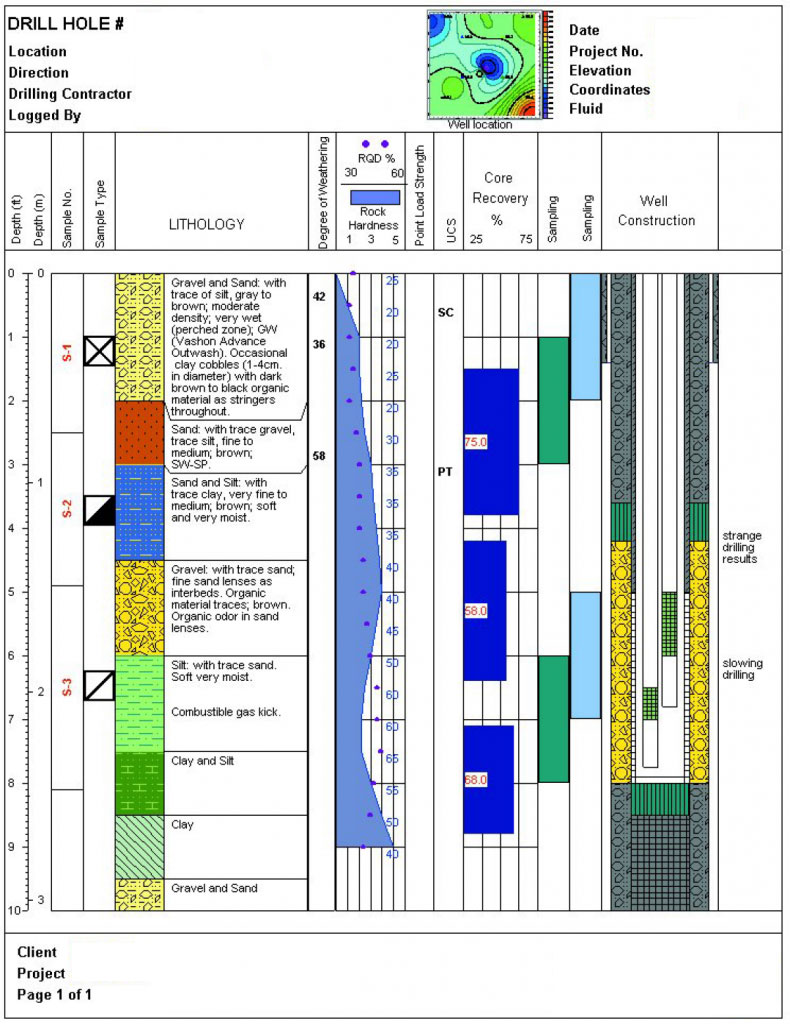

- Stratigraphic information / borehole logs (like the above)

- Contaminant types and concentrations

- Plume configuration / dimensions

- Depth to groundwater

- Remedial objectives

- Sensitive receptors

- Access / installation constraints

- Remedial timeframes

- Budgetary constraints

Basically, a general understanding of the contaminant situation and site conditions, as well as the remedial objectives and any constraints is needed to develop any remedial design. If this is all the information that is available regarding the project, it is still enough to develop a conceptual scope of work and associated estimates of cost and schedule to implement.

But in many cases, more detailed information is available, such as:

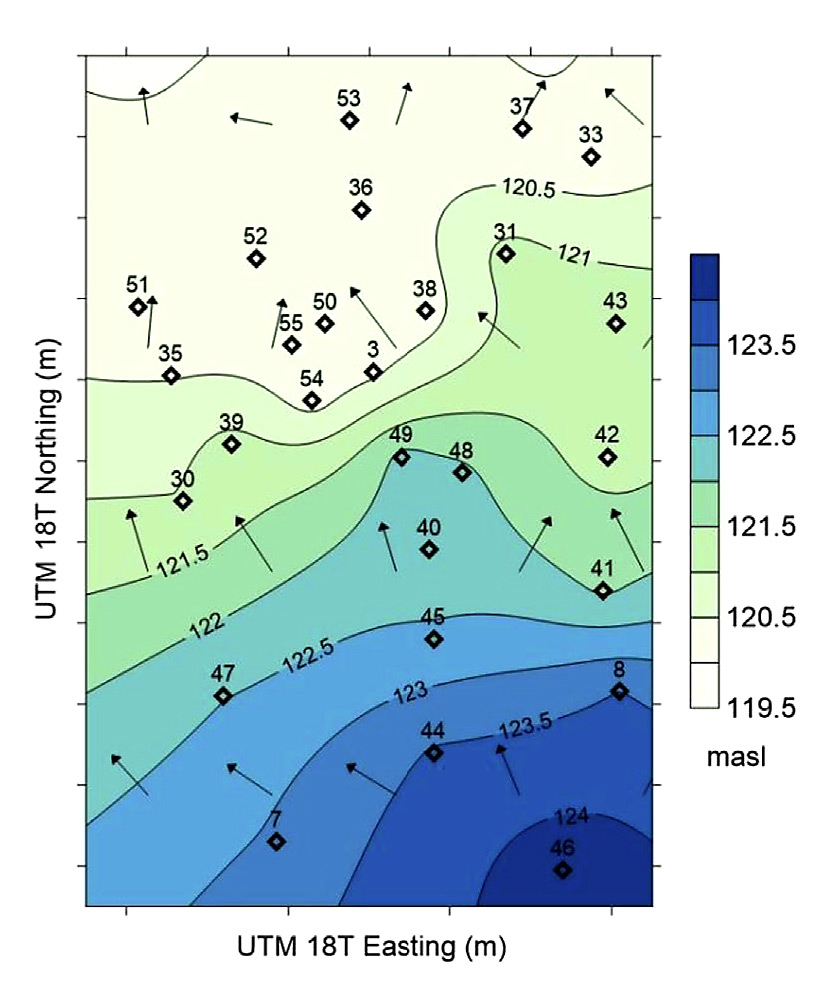

- Groundwater level contours / flow directions (like the above)

- 2D contaminant distribution plans

- Estimates of groundwater flow velocity

- Base of contaminant plume / presence of a confining layer

- Increasing, decreasing or steady state plume configuration

- Location and presence of soil or sorbed contaminant mass

- Groundwater field readings (e.g., pH, ORP, DO, etc.)

This “added benefit” information typically allows a more refined and accurate remedial design to be developed for the site. If that is the level of remedial design required, and there are significant data gaps in the understanding of site conditions or uncertainties in the site’s anticipated response to treatment, additional site characterization activities (such as using High-Resolution Site Characterization), bench-scale treatability studies and/or pilot-scale testing can be completed to obtain adequate information to allow such a refined remedial design to be developed.

In a “perfect world” a very detailed CSM would be available for the site, including:

- 3D contaminant distribution information (like the above)

- Seasonal variabilities

- Subsurface heterogeneities

- Measurements of hydraulic conductivity

- Measurements of hydraulic gradient

- Fracture porosity information

- Detailed geochemistry

- Contaminant mass flux estimates or models

While this level of detail is not available (and likely not needed) for all but the most complex or sensitive sites, when it is available it results in the most accurate and certain remedial design that can be developed for a given site.

Remedial Design Implementation

Obviously, once all is said and done and an appropriate remedial design has been developed for the site, it still needs to be implemented. There is no point in going through all this effort if the remedial plan is not properly executed in the field. Therefore, it is very important to retain a qualified environmental remediation contractor that has the proper regulatory permits, expertise and experience in implementing remedial designs. One that also has the ability to execute the design as planned, provide the necessary oversight and record keeping in the field, and can implement a robust monitoring and QA/QC testing program to validate the implementation.

Vertex brings unparalleled technical expertise, experience, creativity and innovative technologies to site remediation challenges. This allows us to develop and implement innovative, cost-effective, and successful remedial design and risk management solutions. And we have the track record to prove it!

Feel free to reach out to us with any of your remedial design questions or needs: info@vertexenvironmental.ca