It’s Patio Season for Soil Microbes Too!

They’re just waiting for the table to be properly set

The start of summer means sunshine and warm weather, drinks on the patio, and some tasty morsels to share with friends and family. But what if you got to the restaurant, placed your order and the food arrived only to find out there are no plates, napkins or maybe even cutlery with which to eat? You probably wouldn’t be too happy. You might even leave without eating and you certainly wouldn’t tip!

Much like you and I, soil microorganisms, or microbes, like nothing better than to sit down with family and friends to dine. Only in their case they’re looking to dine on organic contaminants, not a caprese salad. In many cases, it’s a matter of feast or famine for them. They flourish when soil temperature hits the optimal range of over 20°C and start to get pretty hungry. A bioremediation contractor’s job, like a good waiter, is to help those microbes along by essentially “setting the table” properly for them: providing the nutrients, moisture, oxygen and/or other conditions they need to satiate those hungers to our benefit.

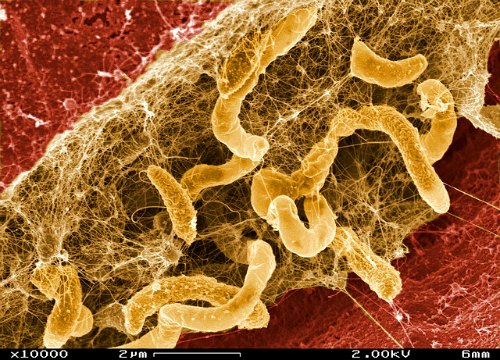

Magnified View of Soil Microorganisms

However, unlike the controlled environment of a restaurant where a waiter can just run back to the kitchen to grab that missing fork, contaminated subsurface soil and groundwater is not as simple to serve up. Acclimated microbes are certainly there at the table ready to eat. The food (contamination) has already arrived as well and there’s probably a lot of it. The microbes may also have been there, laying dormant for years or decades, just waiting for the right conditions to once again thrive, multiply and start eating just about any organic molecule encountered. These include many of the contaminants we often encounter at brownfield and other impacted sites, such as chlorinated solvents like PCE (tetrachloroethylene) and TCE (trichloroethylene) and petroleum hydrocarbons (PHCs). Given the ubiquity and almost infinite adaptability of microbes, why not take advantage of their natural abilities and hungers to remediate (dine on) the contaminants at your site and convert them into harmless by-products, at less cost and without generating wastes? Why not indeed?!

Bioremediation has many advantages over some other forms of site remediation:

- It can be completed either in-situ or ex-situ and under aerobic or anaerobic conditions (with or without oxygen)

- It is compatible with other common remedial technologies, such as treatment systems or chemical oxidation, as a polishing stage

- It is a more passive and less disruptive approach (read: less expensive) when completed in-situ – inject the amendments and let the microbes do their thing

- This means that bioremediation concepts can also be incorporated into PRBs (Permeable Reactive Barriers) to prevent contaminant migration to sensitive receptors

- No wastes are generated unlike excavation and off-site disposal, albeit it does need the luxury of time (and space if completed ex-situ)

- By-products typically include carbon dioxide, water and innocuous mineral salts (and don’t worry; once their food source has been exhausted the microbes will die off and the population will return to pre-remediation levels)

Ex-Situ Bioremediation Taking Place at the Port Lands Flood Protection Project (photo credit: Waterfront Toronto)

So, how can we take advantage of soil microbes to help remediate your site? We need to create the proper conditions for the microbes to proliferate and remediate the contaminants present. We just need to finish “setting the table” for them. This is the main principal behind bioremediation.

What Contaminants Can (and Can’t) be Bioremediated?

Bioremediation has been used for a wide variety of environmental contaminants to date and new microbes are being discovered or enhanced to treat an even broader range of contaminants. Apart from chlorinated solvents and PHCs, many other contaminants are routinely remediated microbially, including:

- BTEX compounds (benzene, toluene, ethylbenzene, xylenes)

- Pentachlorophenol (PCP)

- Pesticides and herbicides (like DDT, 2,4-D, etc.)

- Nitrogen-containing compounds (like ammonia, nitrate and nitrite)

- Even some heavy metals in groundwater, like arsenic, cobalt, chromium, zinc, etc. (via sulphate-reducing bacteria or SRBs)

Other organic contaminants that are extremely stable and lowly soluble like PCBs, F4 range PHCs and high molecular weight PAHs are very difficult to bioremediate – at least over the short term. Research is currently being completed into applying bioremediation approaches to emerging contaminants like soil sterilants and the PFAS compounds (PFOS and PFOA). However, the one class of contaminants that can’t be bioremediated is bulk heavy metal concentrations in soil as elements can’t be destroyed (outside of a nuclear reactor or particle accelerator that is).

Lastly, only bioavailable contaminants can be bioremediated. More on this below.

For a longer list of contaminants that can successfully be bioremediated please refer to Vertex’s Technology Selection Matrix.

Sometimes a “Head Waiter” is Needed

Sometimes getting bioremediation to work at a site takes a “Head Waiter” with years of experience and the intuition to anticipate or deduce what the diners really need or want in order for them to be happy and finish their meals. One of the main things that first needs to be determined is whether the site just needs to be biostimulated, or is bioaugmentation needed as well? Get the table set properly and you can essentially help your site to “remediate itself” using bioremediation.

Waiter” with years of experience and the intuition to anticipate or deduce what the diners really need or want in order for them to be happy and finish their meals. One of the main things that first needs to be determined is whether the site just needs to be biostimulated, or is bioaugmentation needed as well? Get the table set properly and you can essentially help your site to “remediate itself” using bioremediation.

Apart from a high enough temperature, other necessary pieces of the place setting include having:

- Correct carbon to nutrient ratios to facilitate microbial cell growth

- A proper pH range and an adequate moisture content (especially for ex-situ)

- No otherwise toxic conditions (high salinity, heavy metals, etc.)

- Not too much clay content (for ease of amendment distribution in-situ and oxygen entrainment ex-situ)

- Appropriate microbes present or introduced (bioaugmented)

- Electron donors (usually the contaminant or a fermentable carbon substrate – the food source)

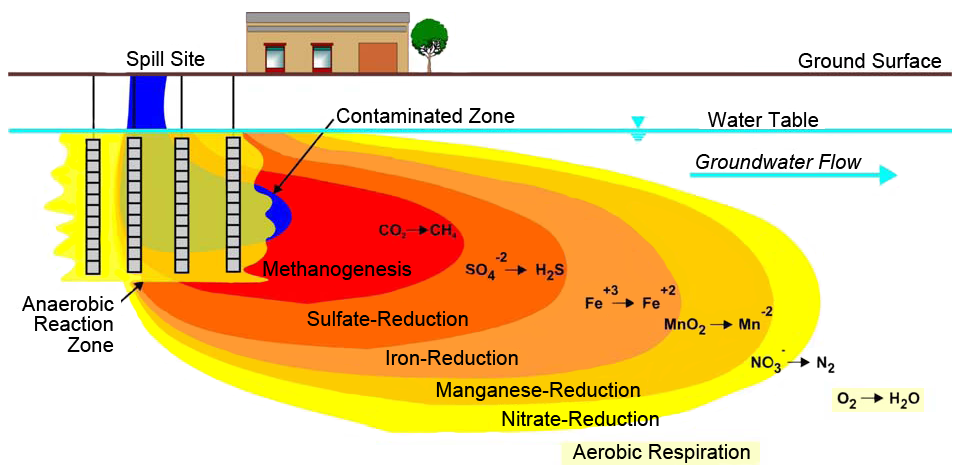

- Electron acceptors (oxygen, nitrate, sulphate, etc.)

Naturally Occurring In-Situ Redox Zones Showing Electron Acceptors (source: US EPA CLU-IN website)

Its also important not to have too much or too little contaminant present. Too much contamination, like the presence of free-phased product (LNAPL or DNAPL), can be toxic to microbes or just take much to long to degrade making bioremediation infeasible. In these cases, pre-treatment to remove the free-phased product (such as using an MPE or other system or surfactant) can be used. Conversely, too little contamination can result in microbes starving from lack of food. In these cases, the addition of a suitable carbon substrate can be used to concentrate COCs and facilitate microbial growth and contaminant destruction. Lastly, in some instances it might take too long for remedial amendments to reach the subsurface areas where bioremediation is needed. In these cases, a recirculation system can be used to increase hydraulic gradients to more quickly distribute amendments throughout the subsurface to where they are needed.

Vertex has a vast amount of experience completing bioremediation for a variety of contaminants. Here is a brief list of some representative examples:

- Anaerobic / In-Situ Bioremediation of PHCs in Bedrock Groundwater:

-

-

- Trap & Treat® BOS 200® was injected into a grid of open boreholes advanced across a plume of PHC impacts in bedrock groundwater to provide long-lasting carbon adsorption and biodegradation of the impacts

-

- Aerobic / Ex-Situ Bioremediation of PHCs and PAHs in Soil:

-

-

- PHC and PAH impacted soil at two sites, including the Toronto Portlands site, is currently being remediated ex-situ using biopiles and windrows that are being dosed with nutrient solutions and then routinely hydrated and mixed to entrain oxygen

-

- Anaerobic / In-Situ Bioremediation of Chlorinated Solvents in Groundwater:

-

-

- PCE, TCE and related degradation products at a former dry cleaner site are currently being remediation using a combination of fast-acting and long-term fermentable carbon substrates, nutrients and KB-1® microbes

-

- Aerobic / In-Situ Bioremediation of PHCs in Groundwater:

-

- A custom blend of low-strength and stabilized hydrogen peroxide, augmented with nutrients, has been used to provide a longer-lasting source of oxygen to remediate PHC impacts in-situ

- Anaerobic / In-Situ Bioremediation of Fertilizer in Soil and Groundwater:

-

- A custom blend of a fermentable carbon substrate, buffering agent and nutrients are currently being used to remediate a nitrogen-based fertilizer spill in-situ using a groundwater extraction, filtration, dosing and reinjection system

It is important to note that not every site can benefit from bioremediation. Vertex was recently asked to assess the feasibility of bioremediating PHC and PAH impacts in soils at a former mine site where previous attempts at ex-situ bioremediation had been undertaken to no avail. Bench-scale treatability testing in Vertex’s in-house laboratory revealed that the soil contained significant amounts of coal. It turned out that the seemingly recalcitrant BTEX and naphthalene concentrations in the soil were in fact present in the coal itself in same ratios!

Coal Fragments Containing Biologically Unavailable Benzene and Naphthalene

The final conclusion was that the soils could not be bioremediated since the contaminants were not bioavailable and so the soils would always exceed regulatory standards as long as the coal was present.

So, is your site’s table almost, but not quite, set to serve up a banquet for those ubiquitous and voracious soil microbes? You probably have the food (contaminants) and the microbes already. All you might need is an experience remediation contractor or to serve as head waiter and finish setting the table properly so the feast can begin. Then those microbes can effectively do their thing and remediate your site in a cost-effective manner. Best of all: no tipping is required!