The 3 Fundamental Factors

Does the slide below look familiar? We have conducted many ‘Lunch & Learn’ sessions to share the latest advancements in remediation technologies. This slide is included in most of our talks.

It’s a simple yet important slide. It summarizes the key fundamentals for successful remediation. We are continually seeking tools to improve on our abilities to accomplish these three critical tasks.

Vertex recently joined the RPI group, a group of environmental remediation companies that have come together for one purpose; to close sites. The foundation of RPI Group success is similar to that of Vertex including, 1) detailed characterization, 2) selection of the appropriate injection amendment, and 3) proper installation techniques. Founding Group member, RPI, Inc., developer of the Trap & Treat® technologies, along with other RPI Group Approved Installers have successfully applied this remediation approach at over 1,500 sites in the US and Europe during the last 10 years. Remedial objectives have been achieved at the majority of the sites, with typically only a single application.

Below we summarize a case study which illustrates the power of high quality implementation of these remediation fundamentals. This project work was presented as a poster at the Battelle Bioremediation Symposium in Miami last month. A special thanks is extended Nathan Thacker of AST Environmental Inc. from Winston-Salem, North Carolina for allowing us to share his work.

An American Case Study:

Benzene Characterization and Bioremediation in Fractured Bedrock

Benzene was detected at concentrations ranging from 38 to 9,300 µg/L in shallow and deep bedrock fractures. The lithology consists of limestone, interbedded with siltstone and shale.

Contaminant Characterization:

A variety of traditional and advanced, high resolution characterization tools were used to define the location and movement of the benzene through the bedrock fractures.

These included nested monitoring wells screened across multiple formations; a 2-dimensional electrical resistivity imaging survey (2-D ERI) to identify weathered zones; borehole geophysical logging to delineate the vertical extent, orientation, and aperture size of the bedding planes and fractures; a heat pulse flow meter to better understand the vertical groundwater gradient controlling the benzene plume; a specially designed straddle packer configuration to enable the collection of discrete groundwater samples from 45 cm (18 inches) zones, isolating samples within the bedding planes/fractures.

Straddle packer system used for injection (left) and discrete groundwater sampling (right)

Delivery System:

Ultimately, the above imaging and monitoring data was employed to design the placement of injection points for delivery of treatment slurries. For example, the 2-D ERI data located weathered bedrock and identified ball-and-pillow structures controlling the transport of the benzene plume. Borehole geophysical data confirmed the varying vertical hydraulic groundwater flow at the site.

Injections could thus be targeted to the exact locations of fractures and bedding planes found to be the pathways for contaminant flow.

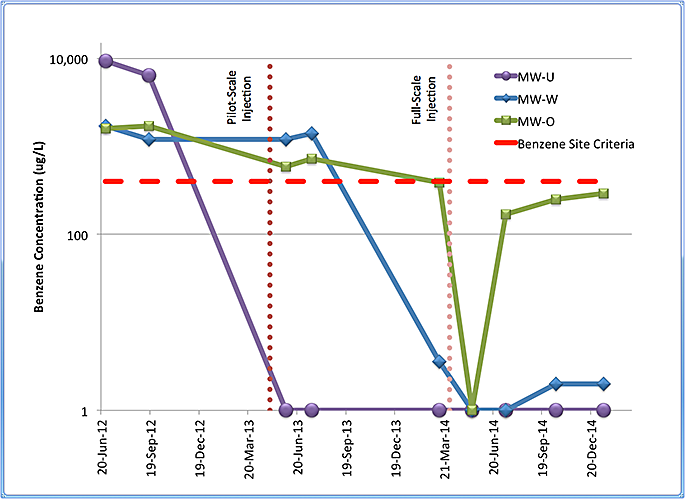

A pilot-scale injection test was conducted to validate slurry delivery. Treatment slurry was injected via high pressure/high flow injections using a specialized pump and straddle packer system. Groundwater data collected post pilot injection confirmed that the targeted monitoring well, with historical benzene concentrations greater than 6,000 µg/L, remained below target clean-up goals of 400 µg/L for seven consecutive quarters.

Data collected from pressure transducers validated the area of influence from an injection event; the results ranged from 22-60 m at the deeper injection intervals (deeper than 4 m) and up to 15 m in the shallower intervals (less than 3 m).

Remedial Amendment:

Trap & Treat® technology was selected as the best fit for the remediation goals based on the high levels of benzene observed at the site, and the need for long-term treatment to control matrix diffusion.

BOS 200® in a Trap & Treat® formula consisting of activated carbon, nutrients, and a facultative bacteria blend, The carbon “traps” and holds the contaminants, resulting in rapid decreases in free phase and dissolved phase contaminant masses. Biological processes then proceed to “treat” the petroleum hydrocarbons contained within the amendment matrix.

Groundwater data collected post full scale injection demonstrates target clean-up goals have been achieved in all compliance-monitoring wells for three consecutive quarters.

The dramatic remediation data illustrates the power of getting it right when it comes to the three fundamentals of remediation.