Remediating Heating Oil in Bedrock

Back in 2011 a home owner near Ottawa woke up to a nasty surprise – heating oil pooling in his garage and around the foundation of his home, under a crawl space and into his backyard. Emergency response crews were sent in to deal with the immediate concern: removing the accessible free phase petroleum by booms, vacuum trucks, and excavation. Unfortunately, digging was not practical to remove all of the fuel due to the presence of shallow bedrock.

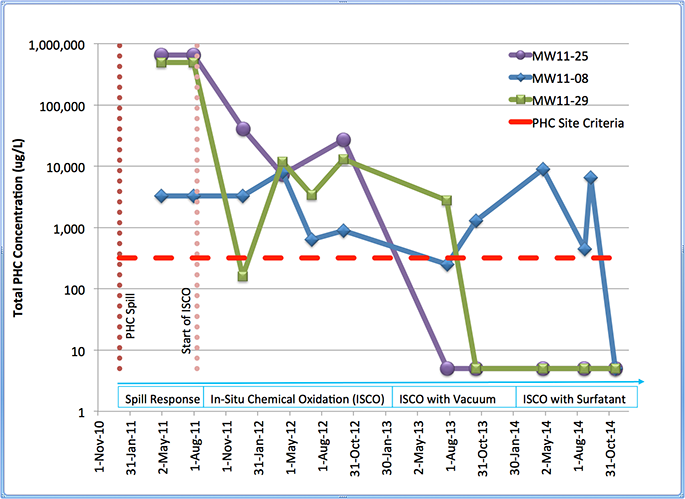

Heating oil migrated and pooled in the underlying bedrock, reaching the drinking water well for the home, in addition to migrating across the site and onto the neighbours property. A vacuum truck initially regularly removed free phase fuel from bedrock wells, however sheen remained and the petroleum hydrocarbon (PHC) concentration remained high. A total of 43 monitoring wells were installed, and of these, 20 wells exceeded the applicable site criteria for PHCs. Most wells exceeded the criteria by several orders of magnitude, with analytical in the 10,000s ug/L, and a maximum of 1,800,000 ug/L.

Given the complexity of the situation, there was uncertainty about how best to proceed.

Vertex had experience on similar sites, and we were able to team with the consultant to develop and implement a remediation plan for the Site. Upon reviewing the site conditions, and remedial options, Vertex developed an in situ chemical oxidation (ISCO) remediation plan applying alkaline activated sodium persulphate. Sodium persulphate is a broad acting oxidant, able to persist in the subsurface for several weeks (important for ensuring adequate distribution and contact with contaminants). Under alkaline conditions, the persulphate is ‘activated’ and results in the generation of sulphate free radicals. These free radicals are even stronger oxidizers, highly effective at degrading longer chain hydrocarbons found in fuel oils (F2 and F3 fractions).

A series of ten (10) fixed well screens were installed within the fractured bedrock to enable injections of the oxidant solutions.

Injections were conducted on roughly a quarterly basis. At each injection event the oxidant was dissolved and then injected into the bedrock wells. Water level readings, groundwater pH, and oxidant concentrations were measured across the site before and after each injection event to validate distribution.

After 3 injections, the highly impacted PHC plume had decreased in both concentration and size, with nine (9) out of the original 20 impacted wells cleaning up. To ensure maximum use of the remaining budget, and to account for the possible presence of free phase in the unsaturated zone, Vertex recommended an enhancement to the oxidant injection program.

Vacuum Enhanced ISCO Injections

Vacuum-enhanced ISCO was completed using a portable vacuum extraction unit. During injections the enhanced gradient allowed for more complete oxidant distribution in both the saturated and unsaturated zones. Following two additional injection events, PHC concentrations from seven (7) additional wells met the Standard, leaving only 2 impacted monitoring wells.

Surfactant Enhanced ISCO Injections

The remaining area (see data on the graph for MW11-08) seemed to represent a discrete and limited area of impact. To completely flush this small area to remove any remaining PHCs, a biodegradable surfactant was injected into the subsurface in the general area. Surfactants promote the desorption and dissolution of petroleum from within soil pores and bedrock fractures. After surfactant application, vacuum was applied to serval wells within the vicinity to recover the newly formed contaminant mass-surfactant mixture.

By the end of 2014, all monitoring well data across the site indicates groundwater quality meets the site standards.

A combination of technologies and a flexible approach is often required to complete site remediation within budget; particularly in difficult geologies and hard to access areas. At this particular site, emergency response crews removed much of the surficial free phase petroleum by vacuum truck and excavation. In situ chemical oxidation was employed to attack the contaminant in place, within the bedrock fractures. Enhancing the oxidant injections with vacuum extractions, and the discrete application and recovery of surfactants, proved to be the right combination of technologies required to achieve the remediation goals.