Overview

In the environmental industry the Permeable Reactive Barrier, or PRB, is a well known technology/strategy when dealing property boundary management and off-Site liability risk for mobile groundwater impacts. In fact, Vertex has already written about these technologies a few times before!

This article won’t review the amazing and versatile continuous passive treatment offered by PRBs. Instead, the focus of this article will be to discuss data gathering and how it relates to quality PRB design and optimization. The basics for designing a PRB are well documented, here a list of the main variables the design team will ask for;

- Contaminant type and concentrations,

- Contaminant distribution (both horizontally and vertically) along the PRB alignment,

- Geology type(s), stratigraphy, geochemistry, groundwater hydraulics,

- Groundwater flow velocities, and

- Any seasonal fluctuations in groundwater elevations.

Additionally having a groundwater treatment target is imperative to understanding the objective of the PRB and what the clean-up criteria is on the downgradient side.

Collecting these parameters can seem like a dauting task as well as costly, especially if multiple rounds of data collection is needed. Many have wondered if there was a faster and cheaper way to screen data along the length of a proposed PRB alignment.

HRSC Tools deployed on-Site

Efficient Data Gathering

Well, that bring us to the primary point of this article! There is a quick and efficient way to profile PRB alignments. High-Resolution Site Characterization (HRSC) tools have been operating in Canada for years and their use has adapted and incorporated targeted data collection, resulting in an overall pre-remediation approach termed Remedial Design Characterization (RDC) sampling.

When PRB’s were first introduced to the environmental industry, 30 years ago, the main approach for data gathering was more rudimentary, including the use of test pitting, monitoring wells and pumping or slug testing. While all of these approaches are still in use today, data gathering and interpretation has come a long way. HRSC tools can gather a variety of data with one push, including soil type, subsurface permeability, and contaminant type/distribution, and then display the information in real time. This allows for flexible and adaptable investigation programs. With regards to RDC, data gathered with the HRSC tools can provide the necessary detailed screening such that targeted analytical can then be collected. This total approach strengthens the PRB design and can be completed in one mobilization.

An important side note is how well the HRSC tools can help a remedial practitioner to understand subsurface permeability. Permeability can change significantly over a short distance, both horizontally and vertically. Understanding variations in contaminant flow patterns (contaminant flux) across the PRB alignment can be critical for a successful design and implementation. Afterall, nobody wants to go to all the effort and install a PRB only to have it fail, or perhaps worse spend twice the amount on it due to a lack of understanding.

Case Study

This case study details the use of HRSC and how it benefited PRB design and installation.

Site History: The Site is located in northern Ontario with known Light Non-Aqueous Phase Liquid (LNAPL) and dissolved phase Petroleum Hydrocarbons (PHCs) migrating towards a sensitive receptor, a large river. To complicate the matter the Site had a large elevation change moving towards the downgradient river. There were limited number of useful groundwater monitoring wells on-Site along the proposed PRB alignment.

Data Gaps: Approximately seven (7) groundwater monitoring wells were originally incorporated in the original 75 m length PRB conceptual design. However, these monitoring wells were installed at various elevations, screen depths, and over many different years. The data was variable, and deemed to be insufficient, but to be fair the HRSC tools were not available when Site investigation work began.

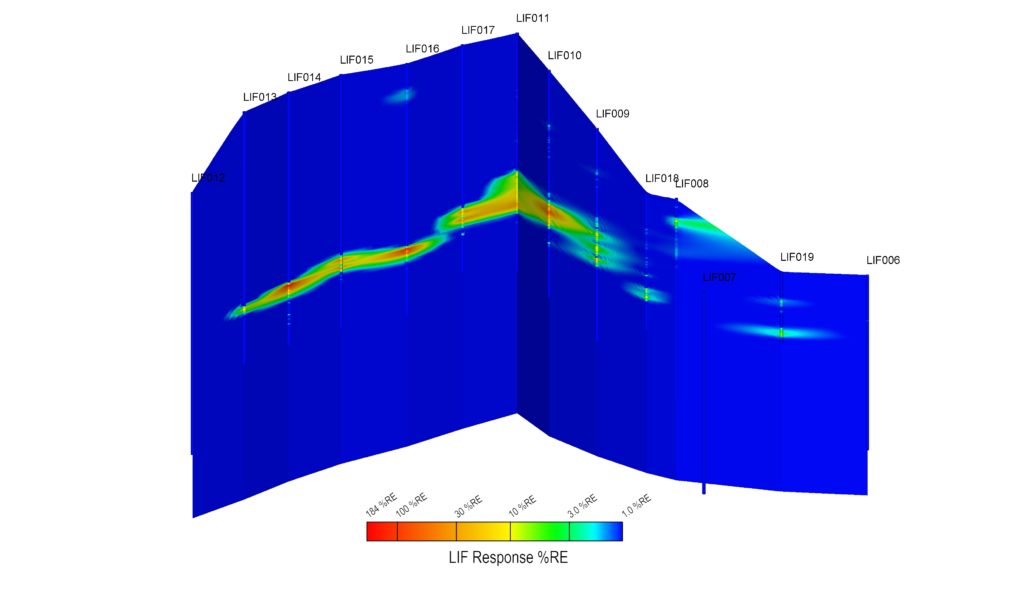

HRSC: Vertex was retained to design the PRB. After a single mobilization both Laser Induced Fluorescence (LIF) and the Hydraulic Profiling Tool (HPT) were deployed and used for four (4) days on-Site. Incredible detail was obtained including LNAPL type and distribution (on a vertical centimeter scale), plus details on soil type, subsurface permeability and the estimated hydraulic conductivity along the 75 m proposed PRB alignment.

LIF Results Along Proposed PRB Alignment Showing location(s) of Potential LNAPL

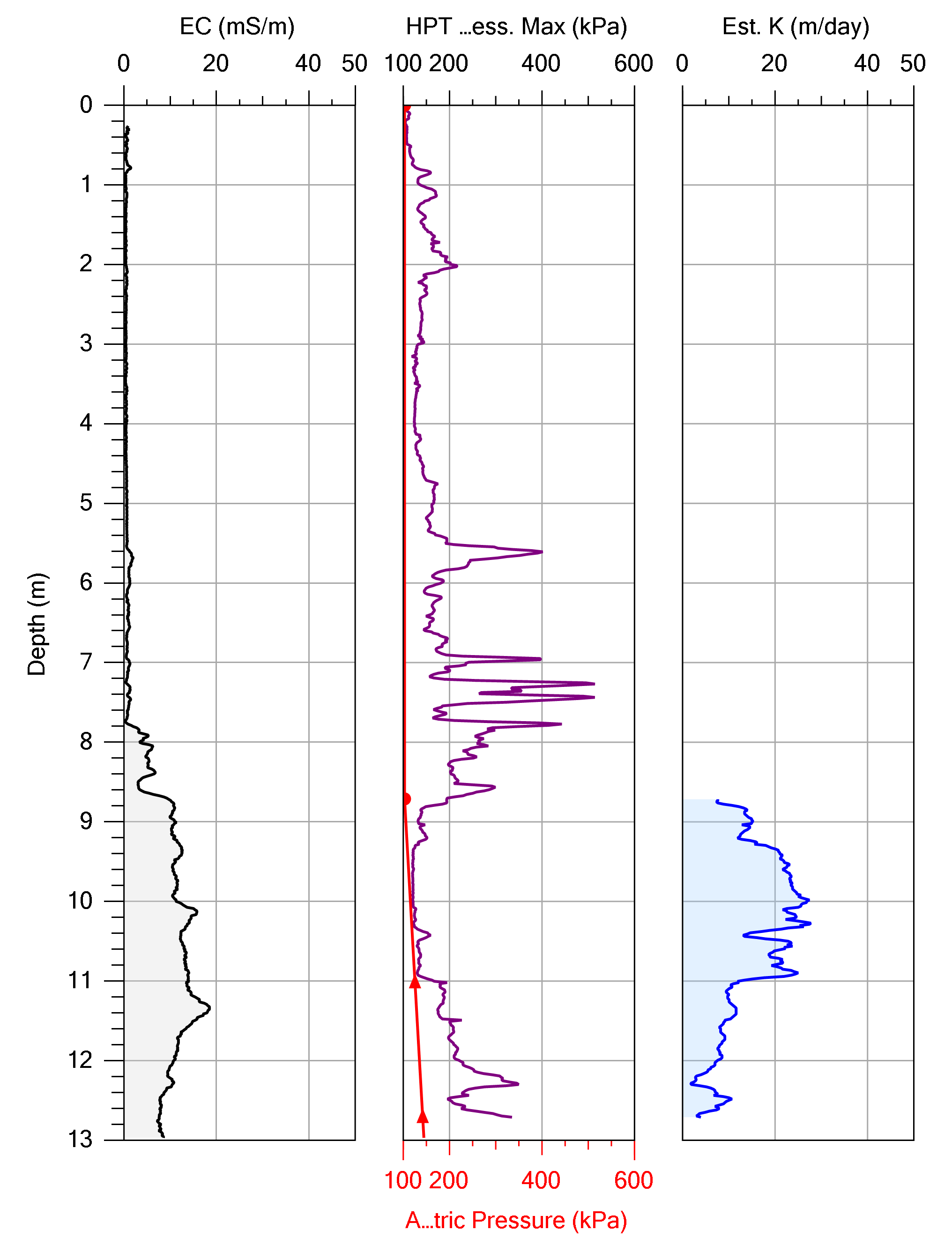

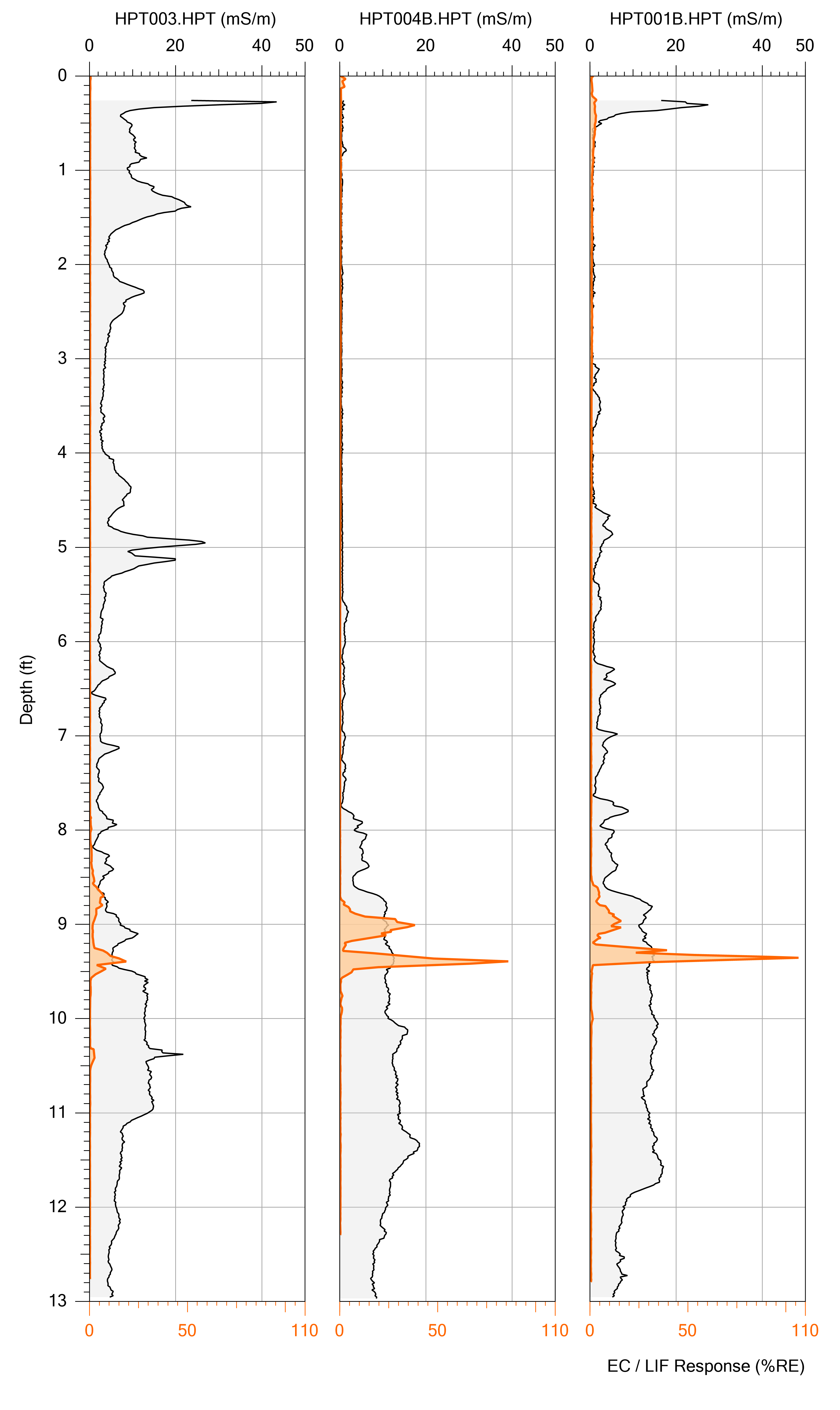

The HPT was able to determine the water table depth, soil type (using EC data), subsurface permeability (using HPT Pressure) and estimate the hydraulic conductivity (K) for locations along the PRB alignment and upgradient on-Site.

Example HPT Log from Site

For those locations where both LIF and HPT profiles were collected, the data could be shown together to allow for further insight into how the LNAPL was situated in relation to the water table, soil type and conductivity zones:

Examples of Co-Related HPT and LIF Logs with LIF Response (Orange) and Electrical Conductivity (Black/Grey)

After the HRSC survey was completed it was noted that LNAPL was detected at elevations that was not known based upon the original site data. Revisions to the PRB design were completed to account for the full suite of the HRSC data and submitted for approval. The approval was quickly authorized, the PRB was successfully installed, and is functioning as designed.

Closing

The sheer volume of quality data that can be gathered in a relatively short amount of time with the HRSC tools can lead to shorter and more detailed delineation, with more robust remedial design with fewer mobilizations and guess work/assumptions. This approach leads to a robust and complete PRB design.

Feel free to contact Vertex Environmental if you have any questions regarding HRSC tools, PRBs, or for any other remediation need.