Contaminant back diffusion from soils and bedrock may be one of the most important factors to consider during in-situ remediation. The ITRC states that “At many sites back-diffusion can sustain plumes long after source removal and result in very long time frames for complete restoration of groundwater plumes.”

For years the environmental industry has been demanding an injected material that is effective over the long term to address back-diffusing contaminants.

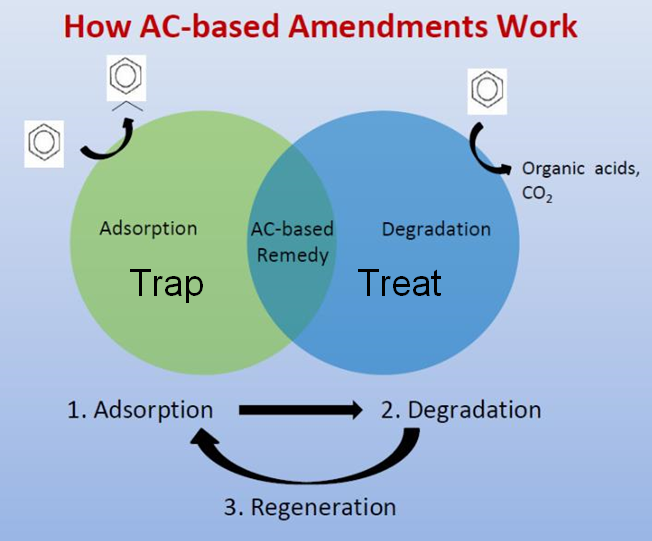

The Trap & Treat® Amendment

Trap & Treat® activated carbon amendments entered the Canadian in

-situ remediation market in 2015 and since that time have routinely been demonstrated to provide full remediation with a single application at most sites.

The original two main injection amendments were:

- Trap & Treat® BOS 100® for chlorinated solvents treatment

- Trap & Treat® BOS 200® for petroleum hydrocarbon treatment

As of 2022 there are two more amendments in the Trap & Treat family that are available in Canada:

- Trap & Treat® CAT 100 for chlorinated solvents treatment, including DNAPL

- Trap & Treat® BOS 200+® for petroleum hydrocarbon treatment, including LNAPL

Remediation Products Inc. (RPI), the inventor of the Trap & Treat® line of remedial amendments, also offers cradle-to-grave, pro bono laboratory analytical in their Quality Assurance Laboratory, to provide detailed quantitative data to support the upfront design and for post-application performance monitoring purposes. This is an incredible added benefit that is offered free of charge to ensure that the right design is developed for your site.

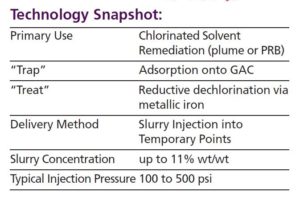

Trap & Treat® BOS 100® and CAT 100

BOS 100® consists of activated carbon impregnated with elemental iron. First, contaminants are “trapped” by the carbon, and then “treated” by reaction with the elemental iron. CAT 100 is a catalyzed form of BOS 100® that combines the adsorptive and chemical reductive powers of BOS 100® with an additional biological-enhanced reductive dehalogenation treatment mechanism.

BOS 100® consists of activated carbon impregnated with elemental iron. First, contaminants are “trapped” by the carbon, and then “treated” by reaction with the elemental iron. CAT 100 is a catalyzed form of BOS 100® that combines the adsorptive and chemical reductive powers of BOS 100® with an additional biological-enhanced reductive dehalogenation treatment mechanism.

BOS 100® was developed for rapid and long-term remediation of chlorinated solvents with typically only a single application. CAT 100 was developed to target soils and groundwater highly impacted with halogenated compounds (even at DNAPL levels) and complex mixes of recalcitrant contaminants typically addressed through combined remedies. Both BOS 100® and CAT 100 are applicable for plume or PRB treatment of chlorinated solvents in various geologic settings including overburden materials as well as fractured bedrock environments.

Benefits of BOS 100® and CAT 100 Remediation

- One application is typically required because of the robust delivery approach and the on-going capacity of activated carbon to address desorption rebound

- Immediate mass reduction and plume control since carbon traps contaminants in place while iron degrades and/or reductive dehalogenation mechanisms them over time

- Less health risks since no release of toxic break-down products

- Treatment down to low parts per billion (ppb) concentrations can be achieved

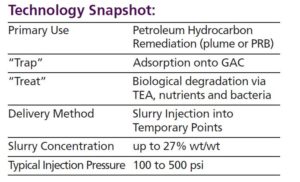

Trap & Treat® BOS 200® and BOS 200+®

BOS 200® consists of activated carbon, terminal electron acceptors (TEA), nutrients and a facultative blend of aerobic and anaerobic microbes. First, contaminants are “trapped” by the carbon, and then “treated” by biological degradation. BOS 200+® adds additional complex carbohydrates, microbes and other compounds into the BOS 200® mixture to supports vigorous and persistent decomposition of LNAPL, lube oils, crude oil, etc.

BOS 200® consists of activated carbon, terminal electron acceptors (TEA), nutrients and a facultative blend of aerobic and anaerobic microbes. First, contaminants are “trapped” by the carbon, and then “treated” by biological degradation. BOS 200+® adds additional complex carbohydrates, microbes and other compounds into the BOS 200® mixture to supports vigorous and persistent decomposition of LNAPL, lube oils, crude oil, etc.

BOS 200® was developed for rapid and long-term remediation of petroleum hydrocarbons with typically only a single application being required. BOS 200+® was specifically developed for significantly impacted sites and heavy hydrocarbons. Both BOS 200® and BOS 200+® are applicable for plume or PRB treatment of petroleum hydrocarbons in various geologic settings including overburden materials as well as fractured bedrock environments.

Benefits of BOS 200® and BOS 200+® Remediation

- One application is typically required because of the robust delivery approach and the on-going capacity of GAC to address desorption rebound

- Works in variety of soil conditions because the biological degradation is first aerobic (oxidation) and then anaerobic (nitrate and sulphate reduction)

- Non-toxic and it has no adverse impacts on soil properties or groundwater quality

- Treatment down to low parts per billion (ppb) concentrations can be achieved

Remediation Products Inc.

Trap & Treat® products were developed by Remediation Products Inc. (RPI). Here’s the storey on the products, and the process and people behind them that makes them such a success:

RPI Group has developed a network of approved installers around the globe. In 2015, Vertex became the first licensed applicator of Trap & Treat® products in Canada.

Contact us to find out if Trap & Treat® is the right solution for your site: info@vertexenvironmental.ca