Delivering Success: Remediating Bedrock and Other Complex Geologies!

Have you ever encountered a site where difficult subsurface conditions left you wondering whether remediation was even possible? Maybe the site had impacts in bedrock or other tough stratigraphy such as flowing sands, cobbles and boulders, and/or tight tills. These geologies can be complex and come with challenges when it comes to remediation. Fortunately, with regards to in-situ remediation, new delivery methods for remedial amendment are available that can allow remediation to be completed even in the toughest of subsurface settings where traditional approaches may not be feasible.

Cross-Section of a Sandy, Bouldery Till

Historically, before remedial technologies had sufficiently advanced, contamination in these complex geologies was commonly address through Risk Assessment (RA) due to the difficulties, uncertainty, and high costs of remediation. However, an RA approach can be a long and arduous process and some sites don’t have the luxury of that much time. Moreover, if non-aqueous phase liquid (NAPL) is present, an RA may not be allowed by regulators unless the NAPL is impractical to remove, non-mobile and/or not near a property line, necessitating some form of remediation.

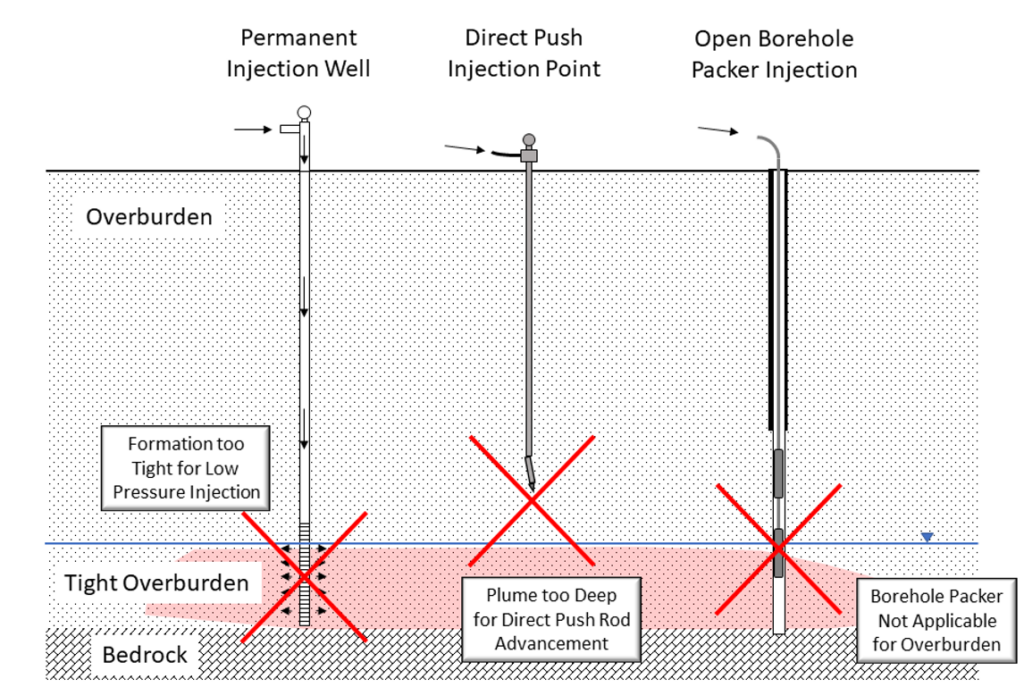

Moving on from RAs, there are three traditional techniques that can be and still are used for injecting remedial amendments to achieve in-situ remediation, each with their own pros and cons.

The Three Traditional Remedial Injection Techniques

| Approach | Injection Wells | Direct-Push Injection Points | Open Borehole Packer Injection |

| Pros |

|

|

|

| Cons |

|

|

|

However, when remedial injections are required in more complex and challenging geologies these traditional approaches may not be feasible at all. Fortunately, there are a several new techniques that have recently been developed to expand the in-situ remediation toolbox, which are the main focus of this newsletter.

Pressure Packers

To treat contaminants within more competent, fractured bedrock matrices, open boreholes can be drilled into the bedrock and injections can be completed using a pressure-packer assembly. This approach allows for higher injection pressures to be achieved (compared to injection wells), resulting in a larger radius of influence and requiring fewer injection points (saves on drilling costs). Moreover, specific fracture zones, identified through pre-injection downhole geophysics, can be isolated and targeted using this approach. Remedial amendments in the form of particulate suspensions and slurries, as well as solutions, can be injected through pressure-packers. In fact, this is the go-to method used to complete remedial injections in bedrock regimes. More detailed information on bedrock remediation capabilities can be found on our bedrock remediation webpage.

To treat contaminants within more competent, fractured bedrock matrices, open boreholes can be drilled into the bedrock and injections can be completed using a pressure-packer assembly. This approach allows for higher injection pressures to be achieved (compared to injection wells), resulting in a larger radius of influence and requiring fewer injection points (saves on drilling costs). Moreover, specific fracture zones, identified through pre-injection downhole geophysics, can be isolated and targeted using this approach. Remedial amendments in the form of particulate suspensions and slurries, as well as solutions, can be injected through pressure-packers. In fact, this is the go-to method used to complete remedial injections in bedrock regimes. More detailed information on bedrock remediation capabilities can be found on our bedrock remediation webpage.

But what do you do when you are in the “in-between zone” where the site geology is not direct-push friendly and/or the bedrock is not competent enough to support an open hole to allow pressure-packer injections?

This is where the Geological Targeted Access Point, or GeoTAPSM, approach comes in to play.

GeoTAPSM Pre-Drill Process

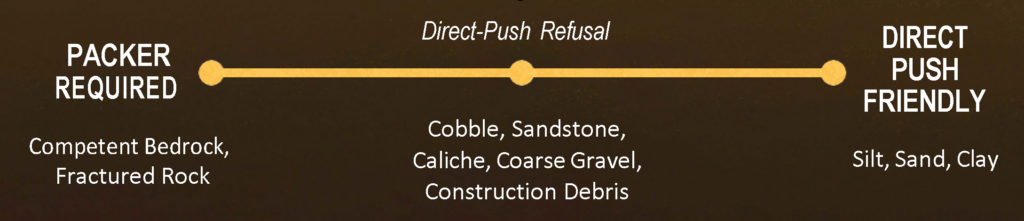

At one end of the spectrum, we have typical direct-push injections in suitable overburden (i.e., sand, silt, and clay) and on the other end there is competent, fractured bedrock injections using pressure-packers. The GeoTAPSM approach perfectly fills the gap in between. Some overburden soils such as tight tills, cobbles, and flowing sands can result in refusal of direct-push tooling and sometimes open boreholes are not stable due to weathered and friable bedrock conditions (i.e., borehole collapse). The GeoTAPSM approach provides an effective solution for targeting these scenarios. In short, GeoTAPSM consists of:

- Advancing a pilot-hole to the target depth using appropriate drilling methods (i.e., augers, rotary, or sonic).

- Backfilling the pilot-hole with hydrated bentonite and allowing at time for it to set-up.

- Advancing direct-push injection tooling through the bentonite-filled pilot-hole to facilitate the injections.

Check out this video of the GeoTAPSM approach in action:

The case study presented in the second part of this newsletter demonstrates how effective the GeoTAPSM approach was at allowing a permeable reactive barrier (PRB) to be injected into friable bedrock at a chlorinated solvent site that would not support an open hole pressure-packer approach.

The next time you encounter a site with complex and/or challenging geology don’t automatically assume that in-situ remediation is out of the question. With pressure-packer assemblies for competent, fractured bedrock, and the GeoTAPSM approach for friable bedrock, as well as those sites with flowing sands, cobbles and boulders and tight tills, in-situ remediation is still an option!

Feel free to contact Vertex Environmental for assistance with any of your challenging sites.