Overcoming Bedrock Remediation Challenges

“Rock Solid” Usually Isn’t and that Used to be a Real Challenge for Site Remediation

Site remediation work often focuses on contamination present in soil and/or overburden groundwater. In-situ remediation of these media is relatively straight-forward using a variety of technologies as has been detailed in many of our previous newsletters. But what if your site has contamination in the bedrock that can’t be remediated via traditional methods? In the past, bedrock contamination was either not looked for, was ignored, or was addressed via Risk Assessment because of the difficulties it posed to in-situ remediation. Fortunately, that no longer needs to be the case!

With the recent shift of regulators towards requiring complete vertical delineation and remediation of impacted sites, bedrock contamination is becoming more and more frequently encountered, including sites that even contain LNAPL (light, non-aqueous phase liquid) in the bedrock.

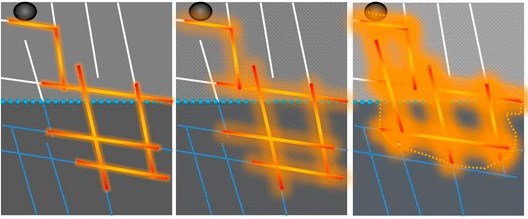

Movement of a Fresh Contaminant Source Through a Fracture Network

and Eventual Diffusion into the Bedrock Matrix (source: ITRC)

There are two established ways and one novel way to effectively remediate bedrock contamination.

- Excavation

- Injection Wells

- Open Boreholes

The injection of remedial amendments directly into the bedrock via open boreholes is a relatively new and exciting advancement in the in-situ remediation world!

Open Borehole Injection Approach:

Open Borehole Injection Approach:

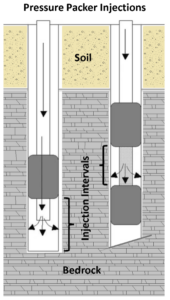

This alternate approach to excavation and injection wells involves drilling open boreholes in the bedrock and completing remedial injections using pressure-packer assemblies. Much higher pressures (compared to injection wells) can be achieved via this approach, resulting in larger radii of influence and requiring fewer injection points. Remedial amendments are not limited to solutions – particulate suspensions and slurries can also be injected via this approach.

Particulate remedial amendments, such as zero-valent iron (ZVI) and Trap & Treat® BOS 100® and BOS 200®, also have the advantage of offering long-lasting groundwater treatment and protection against the effects of back-diffusion of contaminants out of the bedrock matrix and back into the groundwater present in the fracture flow pathways. Because of this it is now even possible to create effective Permeable Reactive Barriers (PRBs) in bedrock.

Click through to continue reading about:

- Remedial approaches / technologies that can be applied to bedrock remediation sites

- Recent examples of different bedrock remediation sites completed

| Read More |

Brute Force: Soil Mixing to Maximize Reagent Loading and Distribution

Finesse has its place but sometimes there is no alternative to brute force! In-situ remediation can occasionally have limitations relating to mass loading and subsurface heterogeneities. These can usually be overcome with creative remedial designs that combine phasing and discrete injection intervals. However, every once in a while, along comes a site where factors line up perfectly to take advantage of a direct soil mixing approach. Vertex recently came across such a site.

A former industrial property was being redeveloped for residential purposes. The entire site had been cleared of buildings and other obstructions. All that remained were relatively shallow (typically less than 6 m deep) plumes of petroleum hydrocarbons (PHCs) and chlorinated solvents (CVOCs) in the soil and groundwater. Redevelopment timelines were short, contaminant concentrations were high, and the impacts were shallow and contained within non-cohesive soils. A perfect scenario for direct placement and soil mixing!

Chemical oxidation (persulphate) was used to tackle the PHCs and chemical reduction (ZVI) was used to tackle the CVOCs. The on-site excavation equipment to strip off uncontaminated, surficial soils down to the water table, directly emplace super sacks of oxidant or ZVI into the excavation cells and thoroughly mix in the remedial amendments throughout the impacted vertical intervals below the water table. Drone footage of this approach makes for interesting viewing!

Click through to watch a short video on shallow soil mixing using Zero-Valent Iron (ZVI).

| Read More |

Feel free to contact us to find out whether soil mixing or another remedial approach is the best option for addressing your contaminated site.