How Do You Spell Remediation Success? C-O-M-B-I-N-E

Consider this brief, but typical summary of contaminated site remediation options:

| Approach | Cost | Result |

| Dig & Disposal (D&D) Only | $1M | No site closure due to contaminant rebound in groundwater |

| Pump & Treat (P&T) Only | $100K | No site closure due to contaminants not fully removed |

| Combined (D&D + P&T)* | $400K | Site Closure |

* can also include other technologies (eg. oxidant emplacement, soil washing, injections)

The numbers and results are illustrative of common differentials we’ve observed first hand on numerous sites. It’s why we are approached, almost daily, to provide a solution to minimize or supplement excavations. Often the quest is to help ensure site closure and/or provide significant budget savings.

The most common drivers?

- Avoiding expensive shoring or underpinning (to enable soil removal), and

- Avoiding extending an excavation program intended mainly for the removal of contaminated groundwater.

Below is a brief case study from the Toronto area where we applied a combined approach to great success. Excavation was supplemented with treatment technologies. Shoring was avoided, large quantities of groundwater were captured and treated on-site, and residual soils and groundwater were treated in-situ. Significant cost savings and the absence of contaminant rebound in groundwater were the rewards.

Step # 1 – Demolition of Commercial Building

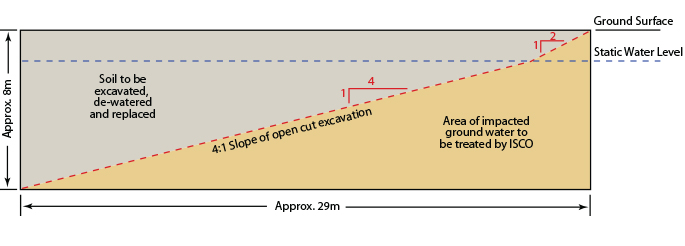

Step # 2 – Excavate Impacted Soil, Except Property Boundary Wedge (to avoid the need for expensive shoring)

Approximately 24,000 tonnes of petroleum contaminated soil removed and disposed off-site. Approximately 11,000 tonnes of low-level impacted soils in contaminated groundwater bearing zone remained un-excavated as a “wedge” of soil adjacent to property boundary.

Step # 3 – Dewater the Excavation

2,600,000 L of petroleum hydrocarbon impacted groundwater was collected, treated on-site, and discharged to the sanitary sewer.

Step # 4 – Install Horizontal Wells for Oxidant Delivery Into the “Wedge”

Highly efficient delivery of petroleum hydrocarbon degrading oxidant is possible with the aid of horizontal wells.

Step # 5 – Inject Oxidants Into the “Wedge”

Residual petroleum hydrocarbons were degraded after two rounds of oxidant injections into the “wedge” using both horizontal injection wells and temporary vertical injection points.

A third injection was planned, but ultimately not required.

Results:

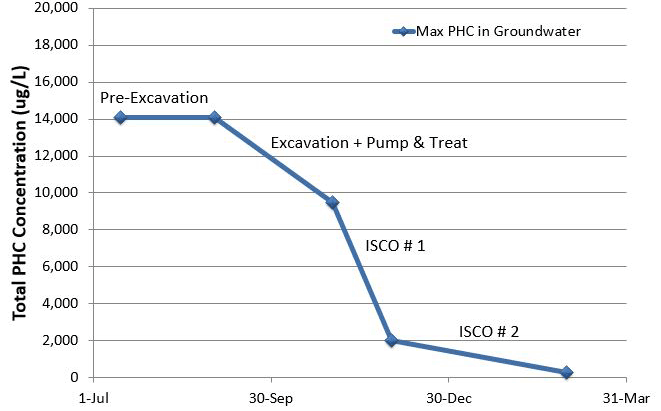

The plotted data shows improvement of groundwater quality after excavation combined with pump and treat to dewater the excavation. Two rounds of in-situ chemical oxidation (ISCO) finished the job!

Conclusions

Direct excavation of contaminated soils is highly effective for source removal. However, many excavation programs reach a point of diminishing returns. Further excavation to “chase” a groundwater plume or to remove residual soil impacts becomes economically impractical.

With some deeper consideration, a range of treatment technologies can be combined with the excavation approach. This combined approach will very often result in a faster, more effective and much more cost effective remediation than dig and haul or pump and treat alone.

Next time you encounter a site requiring source area soil excavation, but where groundwater impacts are also present, consider whether a combined remedial approach may be the better way to go.